The Hear-Wear Patents

What This Series of RIC Patents Provides to the Hearing Aid Industry is a True Hearing Aid Disruption.

Background

Hearing aid development has traditionally been driven by three factors: (1) cosmetics; (2) technology and miniaturization; and (3) packaging, not necessarily concurrently. Patients have always sought hearing aids that were cosmetically appealing, meaning that they were as inconspicuous as possible given the then current technology. Technology and miniaturization have aided cosmetics by producing smaller and smaller hearing aids that are more easily concealed when in use. In addition to cosmetics, technology and miniaturization also have separate goals of providing the best sound quality, and mimicking human hearing as closely as possible. Packaging involves the design and manufacturing of the hearing aid itself to make both construction, fitting, and use as simple and straightforward as possible. The Hear-Wear patents described have resulted in a major hearing aid disruption.

Last week’s post described the major disruption to the hearing aid industry resulting from the these, the Hear-Wear patents. This post describes the practical aspects of this invention.

What is interesting about the SeboTek Hear-Wear patents is that they succeeded by allowing the three hearing aid developmental features to benefit from the innovation, rather than the innovation benefiting from them.

Hear Wear’s Disruptive Hearing Aid Technology

It was within this developmental framework that the SeboTek PAC™ hearing aid was designed – with the goal to integrate all three of these driving factors. These factors could be discussed separately, but it is more logical to discuss them as they impact each other.

Cosmetics

Until the introduction of the SeboTek PAC, hearing aid developments were directed in producing a smaller instrument to fit within the ear canal. Conventional wisdom argued against investment in conventional BTE (Behind-the-Ear) hearing aid development, other than for limited sales of power instruments for individuals having severe-to-profound hearing loss. But, even to meet these needs cosmetically, efforts were engaged in attempting to produce more powerful ITE (In-the-Ear) instruments.

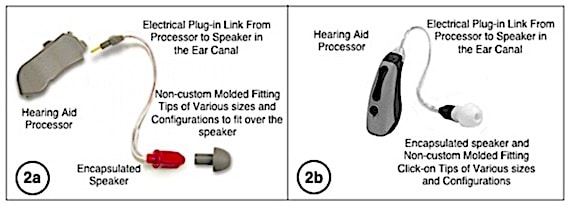

The PAC separated the hearing aid processor from the speaker (receiver), linked them with an electrical wire that was essentially invisible to observers), and embedded the speaker deep in the ear canal with non-custom, size-selectable soft tips (Figure 1).

Figure 1. 1a) Original PAC (post-auricular canal) hearing aid shown separated into its component parts: hearing aid processor, link with speaker (receiver) attached, and size-selectable fitting tip. 1b) Current design shown (not separated as in 1a), although it separates into the separate parts also. This design innovation is now commonly referred to as a RIC (receiver-in-the-canal) hearing aid. Closed or open fitting tips can be used.

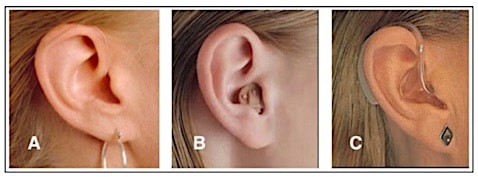

Few dispensers and manufacturers readily captured the significance of this design, that is, until the instrument was worn. Even then, it was more fashionable to criticize and ignore the substantial advantages of the invention – perhaps because of a “not invented here” syndrome, with its usual condescending implications. However, it was not long before even those in doubt realized that cosmetically, the PAC/RIC design provided hearing aids that were less visible than existing BTE or custom-made in-ear/canal devices. This created a marketing advantage related directly to cosmetic acceptance (Figure 2), just what consumers have always demanded. Embedding the speaker more deeply in the ear canal was made possible through prior speaker miniaturization, and coupled with a thin electrical connection to the speaker, resulted in improved cosmetics, but also improved acoustic function.

Figure 2. The SeboTek design (A) is shown when compared with an ITE/ITC (B), and a behind-the-ear hearing aid when worn on the ear. Cosmetics have always, and continue to drive hearing aid design and acceptance.

Design Leads to Acoustic Advantages

With this design came significant acoustic advantages not realized with conventional hearing aid configurations, either of the BTE or custom-molded design.

- Acoustically, the separation of the microphone and speaker provided for significant improvement in gain before acoustic feedback, reducing the level at which feedback reduction circuits had to be employed in hearing aid design.

- Hearing aid speaker replacement, a frequent source of hearing aid failure, was managed easily because the speaker was separated from the hearing aid, and allowed for a quick disconnect. This had an additional advantage of allowing different speakers to be used with the same hearing instrument, and allowed instruments to be interchangeable between ears.

- The hearing aid speaker was now located in its most logical placement for sound delivery – more deeply in the ear canal rather than remotely in the hearing aid processor behind the ear or shallow in the ear canal or concha as with most custom-molded products.

- The speaker placement and fitting tip attachment reduced the peaks and valleys that characterized the plumbing effects of hearing aids that deliver sound through long tubes.

-

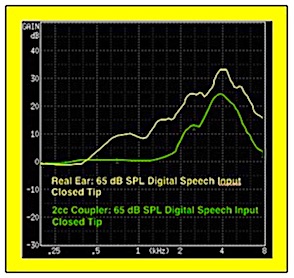

Figure 3. Greater overall sound pressure resulting from having the speaker positioned more deeply in the ear canal (yellow curve) versus the 2cc coupler curve (green).

Greater overall sound pressure resulted, especially in the high frequencies, without added electrical gain (Figure 3). This results from the speaker placement deeply within the ear canal where a smaller residual volume remains between the speaker and the eardrum (Boyle’s Law). This “free” amplification is measured to be approximately 15 dB in the high frequencies that contribute greatest to speech intelligibility. The occlusion effect is minimized because the speaker is inserted sufficiently deep to make appropriate contact with the bony portion of the ear canal.

- Because less sound pressure was required, hearing aid headroom was improved, resulting in less total harmonic distortion.

Design Leads to Subjective Improvements

- The deep positioning of the speaker allowed for relief from the occlusion effect, even with closed coupling.

- The use of non-custom, size-selectable fitting tips eliminated the need to take ear impressions and the problems of ensuring an appropriate fit for comfort and performance. Both vented and unvented replaceable and pre-formed tips could be used for the same instrument, expanding the fitting options for the dispenser.

- Because the electronics, minus the speaker, were located in the processor, the absolute need for miniaturization was circumvented (as was mandated for in-ear/canal instruments), allowing for additional signal processing and additional components in a small hearing aid case (second microphone for directional performance).

- A selection of speaker link lengths compensated for different sized ears to provide for security of fit and maximum cosmetics.

- No ear impression was required to fabricate a custom-molded earpiece. The earmold was replaced with different types of easily replaceable, soft, and flexible tips that were applied during the fitting session. The tips provided significant comfort over hard, custom earmolds.

- Collectively, these features allowed for a same-session hearing aid fitting. This approach allowed a patient to experience amplification during the evaluation process for immediate satisfaction confirmation or adjustment – critical elements for a successful hearing aid fitting, and a feature that had been missing from hearing aid fittings until this invention.

Summary

The Hear-Wear invention, as a disruptive innovation, lead to the following changed applications:

- The hearing aid market was dramatically disrupted (changed, improved, and expanded)

- Custom-molded hearing aids that previously held the prime position for cosmetics, were replaced

- Custom-made earmolds were circumvented for the majority of hearing aid fittings

- Earmold impression taking was eliminated for the majority of patients, eliminating remakes and patient apprehension

- The same session fitting eliminated what were sometimes lengthy waits for product and final fit. Multi-session fittings were reduced

- Hearing aid speakers/receivers could be easily replaced to facilitate repairs and/or additional response performance

- Provided an alternative to occlusion effect management by not being reliant on large vents only. The Hear-Wear invention offered a practical and simple approach to providing a “deep” fit device

- Acoustic feedback was significantly reduced – impacted by separation of the microphone and speaker

- Sound quality was improved using existing components because of the speaker/receiver placement more deeply in the ear canal

- Traditional repair procedures were modified by allowing instant ear coupling replacement where cerumen had been a problem

- Cosmetics and performance were provided in a single innovation

- Open and Closed coupler fitting were optional as distinctive fitting methodologies using similar components

- And, lastly, for a disruptive technology/innovation to quality, the Hear-Wear invention introduced a sustaining technology.