Two previous posts discussed 3D printing. This technology is currently being used in the hearing aid industry, as it is in many other industries, for modeling, and even for some product fabricating, especially earmolds and custom-molded shells for in-ear products. A previous post described Stereolithography (SL) and Selective Laser Sintering (SLS). This post describes two additional 3D printing processes likely to be encountered, Fused Deposition Modeling (FDM) and Multi-Jet Modeling (MJM).

To review, four different types of 3D printing processes likely to be encountered, are:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Multi-Jet Modeling (MJM)

Fused Deposition Modeling (FDM)

This additive manufacturing technology is used to model, prototype, and for production purposes. Although it works by creating an object layer by layer, it differs somewhat from the others in the way the forming materials are used.

In the FDM process a plastic filament is unwound from a coil and supplies material to an extrusion nozzle (Figure 1). The nozzle is heated to melt the thermoplastic material to a semi-liquid state, and has a mechanism which allows the flow of the melted plastic to be turned on and off. The nozzle is mounted to a mechanical platform, which can be moved in both horizontal and vertical directions (X and Y coordinates). As the nozzle is moved over the table in the required geometry, it deposits a thin bead of extruded plastic to form each layer. The plastic hardens immediately after being squirted from the nozzle and bonds to the layer below. Following hardening of a layer, the printer head only then moves vertically (Z-axis) to generate the next layer. Two materials are used by FDM to complete the printing; a modeling material and a support material. The former constitutes the final product, while the latter acts as scaffolding.

FDM 3D printing utilizing the extrusion of thermoplastic material is easily the most common and recognizable 3D Printing process. Because the process is clean and easy-to-use, FDM is suitable for office use. (Video of FDM).

Figure 1. Illustration showing the fused-deposition modeling process, where molten thermoplastic material is deposited in specific patterns. (Reproduction)

Multi-Jet Modeling (MJM)

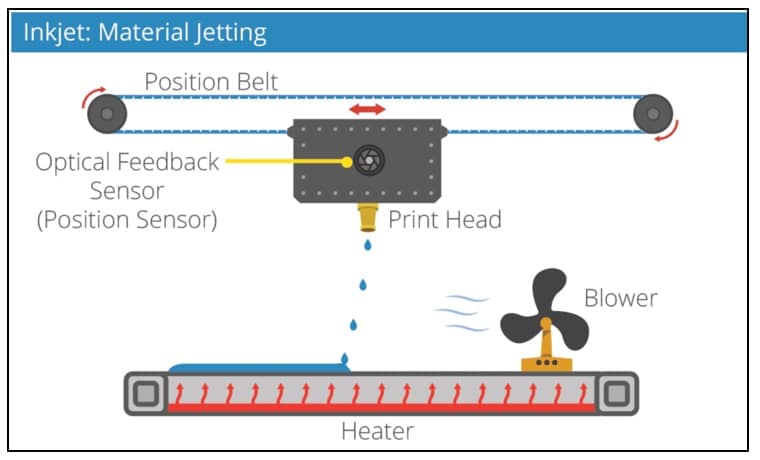

Multi-Jet Modeling (MJM), also sometimes referred to as thermojet, or Material Jetting, works on the principle of a 3D printer utilizing multi-jets. Therefore, the modeling is starkly similar to that of an ink jet printer, but tends to use liquid photopolymers which are cured with a pass of UV light as each layer is deposited. The process is a type of a rapid prototyping process that can create wax-like 3D plastic models, layer by layer.

MJM printers have a head that has dozens of linear nozzles that sprays a colored glue-like substance onto a layer of resin powder (Figure 2). Due to the fact that this technology does not have the same kind of limitations as SLA, it is able to produce exceptionally detailed objects with thickness as fine as 16-microns. However, they aren’t as tough as those created using SLA. (Video)

Figure 2. MJM 3D printing modeling is similar to that of an ink jet printer, but tends to use liquid photopolymers which are cured with a pass of UV light as each layer is deposited. (Reproduction)

This process allows for the simultaneous deposition of a range of materials, meaning that a single part can be produced from multiple materials having different properties and characteristics. MJM printing is very precise and produces accurate parts having a very smooth finish.

Summary

All types of 3D printers build objects layer by layer. The major difference lies in the technique they use to lay down and solidify the raw materials, as well as the nature of the raw materials themselves. Similarly, they require a file format of the 2D slices obtained from the blueprint. Some are clean and simple enough to be used in the home or office, while others are limited to industrial applications. Regardless, rapid advancements in 3D printing bring this technology within the reach of all kinds of modeling and production applications.

When will the first hearing aids be made using 3D printing? This may be some time from now, but in the meantime, modeling, prototypes, and custom in-ear shells and earmolds are already being made using 3D printing.

Featured Image: http://3dinsider.com/3d-printing-guide/