Energy Harvesting Approaches to Powering Hearing Aids

Note: For those expecting to find the continuation of Directional Microphone Mismatch, as mentioned in last week’s post, please note that some recent information has been presented that will relate to improving the robustness of matching two omnidirectional microphones to create a directional listening experience. As a result, the second part is being delayed.

Note: For those expecting to find the continuation of Directional Microphone Mismatch, as mentioned in last week’s post, please note that some recent information has been presented that will relate to improving the robustness of matching two omnidirectional microphones to create a directional listening experience. As a result, the second part is being delayed.

The Battery as a Power Supply

Hearing aids operate using a battery (actually a cell) power supply. These are generally zinc-air cells, but more recently, zinc/silver was introduced as a potential option. The output of the hearing aid battery, or power supply, is advertised as 1.4 Volts, although the actual operation voltage is closer to 1.28 with continued operation down to approximately 1.1 Volts.

The quest for efficient miniaturized energy harvesting devices is an age-old and on-going activity. Before batteries, energy scavenging or energy harvesting was the only way to get useful power (water wheels, windmills, etc.). And, even though energy harvesting is still an active program for many miniature (and larger) devices, current developments have not yet been directed toward hearing aids. The required voltage and current drain requirements for hearing aids appear to be too great at this time for the general energy harvesting approaches employed. Still, energy harvesting (power harvesting; energy scavenging) provides interesting speculation.

Approaches to Energy Harvesting

Energy harvesting is a process of powering an embedded system by “harvesting” energy from the environment. The approaches to date that are most likely to apply to hearing aids are those that attempt to harvest energy to supply the power and storage to autonomously operate miniature electronic devices, such as wireless sensor networks, watches, and biomedical implants. These are devices where battery replacement or recharging is difficult, or where continuous, non-maintenance operation is desired. Whether such operation is desirable for hearing aids is debatable. Regardless, questions about energy harvesting and hearing aids are bound to arise. This short post attempts to describe those harvesting approaches that are most applicable to low-voltage and low-current drain requirements.

Low-voltage energy harvesting generally utilizes ambient energy sources. These consist of:

- Photovoltaic energy,

- Mechanical energy,

- Thermal energy,

- Radio frequency energy, and

- Acoustic energy

Other sources exist for harvesting energy, such as wind energy, salinity gradients, etc., but these are not normally associated with micro-energy harvesting.

Batteries for Hearing Aids

With current hearing aid batteries, it would seem desirable for them to be designed with higher energy density. Unfortunately, battery energy is among the slowest trends in electronic technology. Even though new materials come into play, the energy density doesn’t scale exponentially (Figure 1)[1]. A comparison of battery energy density trend (blue boxes at the bottom of the scale) against recognizable mobile electronic trends is shown in Figure 2 illustrates that battery energy is the slowest trend in mobile computing. Even with new materials, energy density does not scale exponentially[2]. This seemingly intractable problem of how to increase the energy density of batteries has led some to begin thinking about abandoning them altogether, at least for some devices. However, this seems remote for hearing aids at this time, especially if one is looking at energy harvesting for battery replacement.

Figure 1. Energy density by mass shows that for the batteries listed, essentially the processing power doubles every 2 years, but battery capacity doubles only every 10 years. Even though current hearing aid cells (zinc air) are not shown, their growth in energy density does not exceed the battery types listed.

Figure 2. Improvement multiples of computer functions since 1990, with battery energy density improvement shown in comparison (lower blue boxes). It is obvious that battery energy density moves at a much slower pace.

So, if future energy-harvesting approaches might possibly become involved with hearing aid batteries (don’t expect anything soon), what are some of these approaches?

Photovoltaic Energy (PV)

This process converts light energy into electrical energy. The light source is usually sunlight, and the energy conversion uses a photoelectric effect. The problems for micro-miniature devices are that the solar panel(s) has to be large relative to the device, and that use is limited when sunlight is not present.

Interestingly, the use of solar power for hearing aids was attempted back in 1958. However, the hearing aid for which it was developed was a large eyeglass instrument with a fairly long and wide upward-facing surface, something not available in hearing aids today. That device could best be described as “experimental,” and the continued movement toward miniaturization of hearing aids eliminated the solar surface area available. More recent solar rechargeable batteries have been presented, but use a pocket-size recharger for either a wall outlet or solar panel. The energy harvesting is remote from the hearing aid.

Mechanical Energy (PZT)

This energy form arises from mechanical vibrations or body motion. For micro-miniature devices, the random or dedicated body motion (less than about 10 Hz) has been tapped as an energy source. Piezoelectric materials bend to mechanical energy of vibration or stress (Figure 3).

Figure 3. Operation of a piezoelectric illustrating how stress produces a voltage.

Figure 4. Energy harvesting by motion of an oscillating mass.

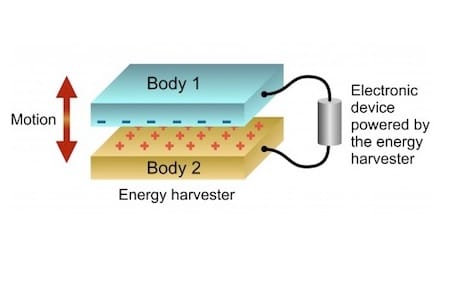

Mechanical vibration energy harvesting has increased in popularity because of the rather abundant availability of such vibrations in many environments. Mechanical vibrations are converted into electricity using electromagnetic induction (vibration leading to motion of a magnetic field), piezoelectricity (to bend or strain a material), and electrostatics (motion of an oscillating mass, Figure 4)[3]. These authors report that magnetostrictive materials, magnetic shape memory alloys, and triboelectrification have also been proposed for vibration energy harvesting. They offer a vibration energy-harvesting scheme based on the charging phenomenon occurring naturally between two bodies having different work functions. They report that WFEH (work function energy harvester) is similar to electrostatic energy harvesting, with the distinction being that neither external power supplies nor electrets are needed. WFEH (Figure 5) is projected to be operated as a charge pump that pushes charge and energy into an energy storage element.

Figure 5. Work function energy harvester (WFEH). Natural vibrations caused by two surfaces with different work functions, repelling and attracting each other to generate electricity. (Image: VTT).

Thermal Energy (TEG)

Figure 6. The thermogenerator converts the heat flow existing between the body part heat and the ambient in electrical energy.

TEG (thermoelectric energy generator) uses temperature difference to generate electric potential. Using the Seebeck Effect (a phenomenon in which a temperature difference between two dissimilar conductors produces a voltage difference between the two substances), this form of energy harvesting is considered reliable and maintenance free, but is costly and inefficient. It often uses the temperature difference between the human body and the surrounding environment (Figure 6). Because this variation between the internal and external temperature is only a few degrees, this would normally produce only about 200 millivolts, which is insufficient to power an electronic device such as a hearing aid that normally requires about 1.2 Volts. [4]. The TEG is limited by Carnot efficiency (Carnot efficiency improves as the range of temperature difference becomes wider).

Radio Frequency Energy

This form of energy harvesting scavenges energy from wireless systems present in our environment (TV, radio broadcast, mobile networks, wireless networks, radar, etc.). It does require that the harvested energy be rectified and filtered to recover DC (direct current).

Acoustic Energy

This is an abundant source of energy harvesting, but it is said to require a Helmholz resonator containing a piezoelectric cantilever beam.

Energy Storage Options

Scavenged energy is not constant, and as a result, power is not available “on demand.” Because of this, the energy storage may be so demanding that it cannot be met by traditional rechargeable batteries, traditional capacitors, or, most likely, not even by super capacitors.

Summary

It is most likely going to be difficult to beat hearing aid batteries for their all-around versatility and flexible space application. However, as with most things, the future is bound to change, most likely initiated by environmental interests.

- Valenzuela, A. (2008). Texas Instruments↵

- Paradiso, et al. (2005). Pervasive computing, IEEE↵

- Varpula, A., Laakso, S., Havia, T, Kyynäräinen, J., and Prunnila, M. (2014). Harvesting vibrational energy using material work function. Scientific Reports 4, Article number: 6799↵

- Generating electricity from body heat, Oct. 2, 2011, http://hassam.hubpages.com/hub/Generating-Electricity-From-Body-Heat↵