At a recent meeting, a group of audiologists were sitting around talking about their experiences with the new rechargeable hearing aids. A question came up about safety and handling of the hearing aids powered by rechargeable batteries. Specifically, a question was asked about mailing aids for repair as well as packing them or accessories in suitcases for travel. The following is a summary of the information available from various sources on the management of hearing aids powered by rechargeable batteries.

Authors:

Barry A. Freeman, Ph.D., Vice President, Business Development, ZPower LLC

Michael Brady, B.S. Chemistry, Associate Research Scientist, ZPower LLC

Jeff Ortega, Ph.D., Director of Research, ZPower LLC

Background

There have been many defining moments in technology advancements in hearing aids since transistors first replaced vacuum tubes, circuits went from analog to digital, and features like wireless streaming were became available to consumers. It now appears we are entering a time when the hearing aid industry is moving:

“to more differentiated solutions such as rechargeable hearing aids…rechargeability was a focus at AAA (2017), with most manufacturers now offering rechargeable solutions…and in the medium- to long-term, we believe it is likely that most hearing aids will be rechargeable” (Goldman Sachs, 2017).

Two rechargeable battery options currently are widely available for hearing aids—silver-zinc and lithium-ion.

Silver-zinc batteries were introduced to the hearing industry by ZPower and are available by most of the global hearing aid manufacturers and in hearable consumer electronics like Bose’s Sleepbuds. Silver-zinc is the oldest battery chemistry, first reported by Volta in 1800 and widely used by the military and space industries. The favorability of silver zinc is that it uses a water-based electrolyte that is non-flammable.

The stability of the silver-zinc battery materials and the complete non-flammability of the silver-zinc electrolyte make it an intrinsically safe battery technology. In addition, when compared to other rechargeable battery chemistries like lithium-ion, silver-zinc does not have size limitations and has a higher energy density.

Lithium-ion batteries were first introduced by Sony in 1991 and, today, are widely used in consumer electronics and wearables.

The first hearing aids using lithium-ion batteries were introduced in 2016 and are available from several hearing aid manufacturers in selected products. Inherent characteristics of lithium-ion are voltages of 3.6-3.7V as compared to the traditional 1.2-1.4V of zinc-air hearing aid batteries. Therefore, lithium-ion batteries require a voltage regulator and additional safety circuits in the hearing aid that increase its overall size and sealing of the battery in the case with no user accessibility to the battery.

Managing Products with Rechargeable Batteries: Shipping Considerations

Silver-zinc rechargeable batteries use a water-based chemistry that is stable, non-flammable, and non-toxic. “They have a long record of safe service in commercial, aerospace and military applications. Manned space flight missions beginning with NASA’s Mercury program successfully deployed rechargeable silver-zinc batteries without any incidents and the military has used silver-zinc batteries in missiles, torpedoes, and submarines for more than five decades” (Dueber, 2008).

ZPower silver-zinc batteries are classified by the U.S. Department of Transportation as Class 8, Non-Hazardous for shipping and handling with no restrictions.

The concerns about the safety of lithium-ion batteries are well documented in the literature as well as the commercial press. Most recently, VARTA Microbattery, one of the leading manufacturers of lithium-ion micro-batteries used in hearing aids, issued the guideline for “Handling precautions, prohibitions and general supply notices for VARTA Microbattery CoinPower Lithium Batteries” (September 2018).

The guideline explains that “lithium batteries provide a high energy density which…contain a certain safety risk. If short-circuited, heat and sometimes sparks may be generated. Mistreatment beyond the recommended limits can cause gas generation, leakage and fire.”

The guideline recommends that manufacturers of products with lithium-ion batteries should provide “comprehensive instructions and appropriate markings for end users. The assembled device shall be provided with packing, handling and safety instructions regarding cell usage, storage, and replacement, and shall be marked with information in accordance with applicable regulations.”

Li and Cui (2018) note that “in the United States alone, a fire in a lithium battery grounds a flight every 10 days on average according to the Federal Aviation Administration” (Li and Cui, 2018).

The International Air Transport Association (IATA) report that “lithium batteries are dangerous goods that can pose a safety risk if not prepared in accordance with the transport regulations. To help with compliance, IATA has developed guidance for shippers, freight forwarders, ground handlers, airlines and passengers” stating that “lithium batteries sent separate from equipment are prohibited and damaged or recalled batteries are prohibited and may not be mailed internationally under any circumstances.”

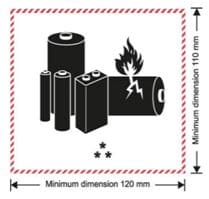

Figure 1. Lithium shipping label must be affixed to packages (IATA Lithium Battery Guidance Document – 2017 APCS/Cargo Page 13 15/12/2016).

Further, the U.S. Department of Transportation classifies lithium-ion batteries as Class 9, Hazardous, with multiple requirements and restrictions on packaging, shipping, and handling.

In addition to the safety tests that all lithium-ion batteries must pass, they also have several restrictions based on the way electronics (i.e., hearing aids and accessories) with the battery installed are transported, shipped, or mailed. For example, when sending more than two products with lithium-ion batteries like hearing aids or accessories (e.g., streamers) in the same package, there must be a lithium-ion battery label (see Figure 1) on the package. The Air Waybill is required to contain the statements “Lithium [ion or metal] batteries in compliance with Section II of PI9XX” when the lithium battery mark is affixed to the package.

If the package contains two or fewer products with an installed lithium-ion battery, then the shipping label and statement on the shipping waybill are not required. These regulations and requirements can add a greater logistical burden for audiologists and dispensers that are trying to bulk ship several products/devices with lithium-ion batteries to a single location (2017 Lithium Battery Guidance Document).

Consumer Considerations

The consumer also is limited to what they can bring on an airplane when they travel. There can be no spare batteries for their devices in checked bags, however they can bring a maximum of 20 spare batteries in carry-on luggage in addition to 15 personal electronic devices with batteries in them.

Although spare lithium-ion batteries for hearing aids currently are not available, hearing aids and accessories powered by lithium-ion batteries must be counted as a part of the permitted maximum fifteen (15) devices. These may include personal electronics such as cameras, cell phones, laptop computers, tablets, watches, calculators, hearing aids and streamers, as well as external battery chargers and portable power packs containing a lithium-ion battery.

Non-Functioning Product Considerations

When a device powered by lithium-ion batteries is not working due to battery problems and is returned for repair, the device only can be shipped by ground transportation. If the battery is damaged, the product cannot be shipped by air under any circumstances, only ground.

The challenge for audiologists and dispensers, of course, is determining whether the cause of a non-functioning device like a hearing aid or accessory is a defective lithium-ion battery which is sealed in the case or, perhaps, a different factor.

Caution is advised and the packaging should be properly labeled and must be shipped by ground. This makes it extremely difficult for international companies to receive returns unless they have a repair facility accessible by ground transportation.

In addition, even if shipped by ground, the shipping company (e.g., FedEx, UPS, USPS) may refuse to send it due to a safety concern for their employees. This issue highlights the possibility that even if all transportation regulations are followed, it is up to the carrier to make the final decision on handling and shipping. These concerns and regulations do not apply to products powered by silver-zinc batteries which, like disposable zinc-air batteries, are not sealed in the case of the hearing instruments and do not have shipping restrictions.

Conclusions:

As hearing technology transitions from disposable zinc-air batteries to hearing aids powered by rechargeable batteries, providers and consumers must be aware of the unique considerations associated with the management of these batteries and the products they power.

References:

- Dueber, R. (2008). Silver-zinc battery tech outshines Lithium on Safety Front. COTS Journal: Journal of Military Computing and Electronics.

- 2017 Lithium-ion Battery Guidance Document.

- VARTA Guideline (2018). Handling Precautions and Prohibitions for VARTA CoinPower Batteries.

A lot of good points comparing silver zinc to lithium ion. The reality, in February 2019, is that only the lithium ions are delivering consistent performance that is meeting user expectations. The roll out of silver zinc has been fraught with poor charging, non-charging, and inconsistent charging. Zpower has been excellent at replacing all of these rechargeable components, often many times for the same user, but those are services that the user never wants to need in the first place. All HCPs look forward to a time when silver zinc is offering the promised flexibility AND a reliable user experience.