Researchers from MIT, Massachusetts Eye and Ear, Harvard Medical School, and Columbia University have developed an innovative implantable microphone that could pave the way for fully internal cochlear implants. This advancement could significantly improve the quality of life for cochlear implant users by eliminating the need for external hardware.

Cochlear implants have improved the hearing of over a million people worldwide. However, these devices are currently only partially implanted and include external components that prevent users from swimming, exercising, or sleeping while wearing them. Due to these limitations, some individuals choose not to use cochlear implants at all.

The UmboMic: A Revolutionary Sensor

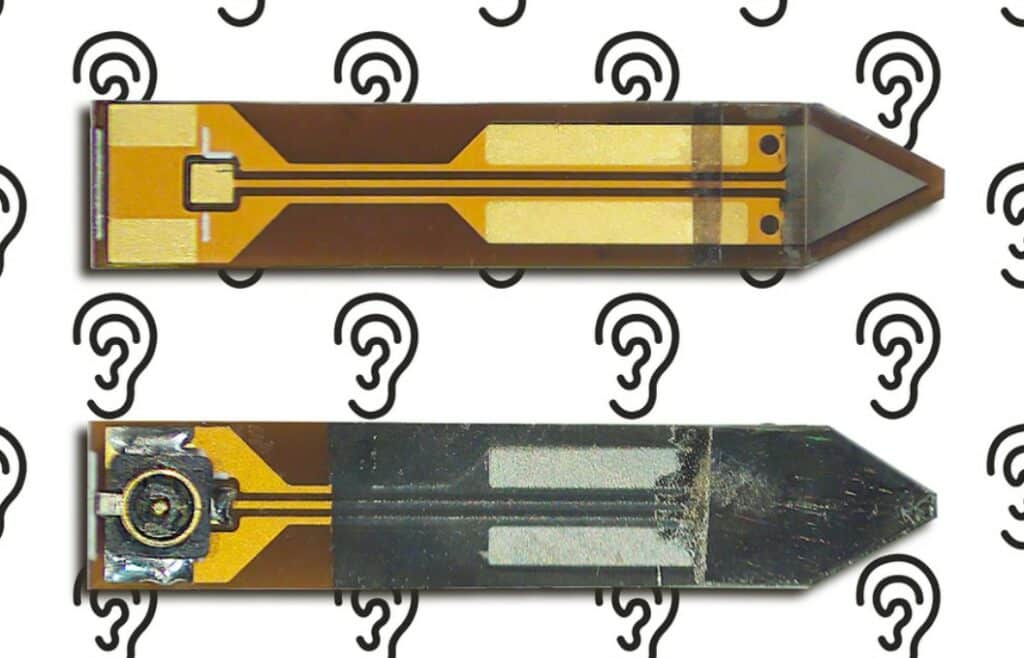

The key innovation is the UmboMic, a tiny 3×3 mm triangular motion sensor made from polyvinylidene difluoride (PVDF), a biocompatible piezoelectric material. This sensor, designed for implantable applications, performs on par with commercial external hearing aid microphones. It targets the umbo, a part of the middle ear that vibrates in response to sound, making it an ideal location for capturing auditory signals.

“Our goal is that a surgeon implants this device at the same time as the cochlear implant and internalized processor, which means optimizing the surgery while working around the internal structures of the ear without disrupting any of the processes that go on in there,” said Emma Wawrzynek, an electrical engineering and computer science graduate student and co-author of the study.

Image showing both sides of the prototype for the implantable microphone. Image credit MIT

Overcoming Current Challenges

Fully implantable microphones offer numerous advantages, including better sound localization and noise filtering. However, existing devices that detect sound through the skin or middle ear bone movement often struggle with capturing soft sounds and a wide range of frequencies. The UmboMic addresses these challenges with its advanced design.

The PVDF layers of the UmboMic are positioned on either side of a flexible printed circuit board (PCB), creating a microphone about the size of a grain of rice and 200 micrometers thick. When the umbo vibrates, it causes the PVDF layers to bend and generate electric charges, which are then measured by electrodes in the PCB layer.

To minimize noise, the team employed a “PVDF sandwich” design, where the positive and negative charges produced by the PVDF layers cancel out electrical interference. The fabrication process was complex, as PVDF loses its piezoelectric properties at temperatures above 80°C. The researchers overcame this by gradually depositing titanium while using a heat sink to cool the PVDF.

Amplifying Performance

The team also developed a custom low-noise, low-power amplifier to boost the tiny signals generated by the umbo’s vibrations without introducing additional noise. This was crucial for ensuring the microphone could detect very quiet sounds effectively.

The UmboMic was tested in human ear bones from cadavers, demonstrating robust performance within the intensity and frequency range of human speech. The UmboMic apparatus achieves an equivalent input noise of 32.3 dB SPL over the frequency range 100 Hz to 7 kHz, good linearity, and a flat frequency response within 10 dB from about 100 Hz to 6 kHz.

“One thing we saw that was really interesting is that the frequency response of the sensor is influenced by the anatomy of the ear we are experimenting on, because the umbo moves slightly differently in different people’s ears,” noted Wawrzynek.

Future Directions and Impact

Researchers are moving forward with live animal studies to further assess the UmboMic’s performance and response to implantation. They are also exploring methods to encapsulate the sensor, ensuring it can safely remain in the body for up to 10 years while maintaining the necessary flexibility. Traditional implant materials like titanium are too rigid for the UmboMic, so the team is investigating alternative materials and mounting techniques to prevent unwanted vibrations.

Karl Grosh, a professor of mechanical engineering at the University of Michigan, praised the innovation:

“The results in this paper show the necessary broad-band response and low noise needed to act as an acoustic sensor. This result is surprising because the bandwidth and noise floor are so competitive with the commercial hearing aid microphone. This performance shows the promise of the approach, which should inspire others to adopt this concept.”

The research, funded by the National Institutes of Health, the National Science Foundation, the Cloetta Foundation in Zurich, and the Research Fund of the University of Basel, was published in the Journal of Micromechanics and Microengineering.

Citation:

- Aaron Yeiser, Emma Wawrzynek, John Zhang, Lukas Graf, Christopher McHugh, Ioannis Kymissis, Elizabeth Olson, Jeff Lang, Heidi Nakajima. The UmboMic: A PVDF Cantilever Microphone. Journal of Micromechanics and Microengineering, 2024; DOI: 10.1088/1361-6439/ad5c6d