By Dr. Daniel R. Schumaier

The Problem

Even with today’s sophisticated hearing instruments, moisture and cerumen accumulation in microphones and receivers causes problems. Moisture can cause distortion, reduce gain, and cause intermittency and ultimately, instrument failures.

Hearing instruments are designed to provide high-frequency, distortion-free amplification. Many amplifiers have directionality features, which incorporate microphones that need to be calibrated to work appropriately. Moisture and debris often reduce the microphone’s proper functioning, thus reducing the directionality feature which is so important for hearing in noise. Most patients that are fit with hearing devices primarily need the higher frequencies for speech comprehension. Moisture accumulates on the diaphragms of the microphones and speakers, thus damping the high-frequency response.

In addition, moisture and bodily oils cause failure of switches and other electronic components in hearing instruments.

Where does the moisture come from?

The body is composed primarily of water. The ear canal has a relative humidity of approximately 65%. Humidity in and behind the ear can range up to 80%-85%. When a patient moves between a warm environment and a cooler environment, microscopic condensation droplets accumulate over time.

Some people perspire profusely, and others get caught in the rain. Hearing aids also accumulate debris, which is composed of lint, cerumen, dead skin, hair, skin products, and other materials. This debris absorbs water, which can clog the microphone and receiver openings. Because of the above, most repairs to hearing aids include replacement of microphones and receivers.

The Answer – Hearing Aid Dryers

An appropriate electronic hearing aid dryer provides an effective and affordable way to remove moisture, helping to improve audio performance of the hearing devices and to extend the life of the device before a need for service and repair.

The Challenge with Rechargeable Hearing Instrument Batteries

The market has seen a dramatic shift away from the disposable zinc air batteries used for years to new rechargeable solutions. And most of these rechargeable hearing devices incorporate lithium-ion or silver-zinc batteries. These batteries are susceptible to failure from high temperatures.

Therefore, the temperature of a drying device for rechargeable instruments must be lower than with standard zinc air batteries. Hearing aid manufacturers typically recommend that the temperature not exceed 95° F for their rechargeable hearing instruments. Most conventional hearing instrument dryers used today reach temperatures above 100° F, with some significantly above that temperature.

The temperature limit for drying new rechargeable aids should be between 80°-85° F. That provides enough heat to break the surface tension bond of the water molecules and permits a fan to move them away from the hearing device for effective drying. While still staying well below the recommended temperature limit for the rechargeable battery technologies. Higher temperature can reduce the effectiveness of, and eventually destroy, the rechargeable battery in the instruments.

Our Innovative New Drying Solution

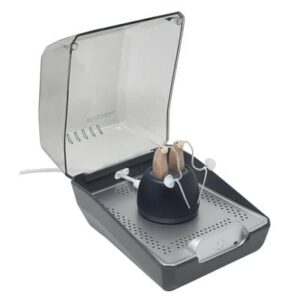

DryBoost UV, ideal for rechargeable hearing devices

Ear Technology has recently launched our latest product in the Dry & Store® family, the DryBoost UV®. With a precisely controlled drying temperature that was designed specifically for use with rechargeable batteries, DryBoost UV is the perfect complement to rechargeable hearing instruments. DryBoost UV incorporates a heater that works with a fan to provide warm air circulation around hearing instruments and their charging base for complete drying.

DryBoost UV also utilizes a UV-C lamp to provide sanitization of hearing instruments while they are being charged and dried. Often hearing instrument users complain of ear infections of the ear canal or itchy ears. Sanitizing the hearing instruments nightly reduces the reintroduction of bacteria into the ear canal, thus reducing ear infections. Itching ear canals are often caused by bacteria that cannot be seen through visual inspection. It is well known that UV-C light of sufficient intensity and duration of exposure can sanitize surfaces, thus reducing bacteria. DryBoost UV uses a high intensity 50mm linear (253.7nm) UV-C lamp with a long-life expectancy. The UV-C lamp with a wavelength of 253.7 nanometers gives a LOG 3 theoretical reduction rate of 99.9% of bacteria.

This product has two cycle options. The first cycle consists of a 5-minute sanitizing cycle, followed by a 6-hour drying cycle. The second cycle option is to sanitize only. This sanitization cycle lasts for 5 minutes and will shut off automatically. A normal 6-hour cycle removes approximately 1 gram (20 drops) of water.

Due to the need to charge multiple devices, DryBoost UV has an extra USB output on the rear of the unit, allowing charging of a phone or other electronic device while the hearing instruments are being cared for and charging inside the unit. Because of the size of the DryBoost UV, many other products can fit within the unit. A few examples are watches, earphones, musician in-ear monitors, hearing streamers, and pocket talkers. All of which can be dried and sanitized inside the DryBoost UV.

DryBoost UV Size

The DryBoost UV accommodates rechargeable hearing instruments and their chargers from a wide range of manufacturers. Various configurations of chargers can sit within the drying chamber. There is a small notch in the back of the drying chamber allowing the cord on the charging base to fit through so it can be plugged in.

The tray is 5.8 inches in length and 4.6 inches wide, with a height of up to 3.5 inches. Large enough to accommodate nearly any of the charging bases currently on the market. If the charger has a closed lid, the lid of the charger will need to be open during the drying and sanitizing cycle for best results. If the charger does not fit directly into the DryBoost UV, simply plug the charger into the USB port at the back of this unit and place it to the side so it can charge. Then place the hearing instruments directly into the DryBoost UV for sanitizing and drying.

DryBoost UV’s Clear Protective Lid

DryBoost UV’s unique design was created based on customers’ suggestions of wanting to be able to see their hearing devices while in their dryer. The clear protective lid inhibits the UV-C light, not allowing it to penetrate through the clear plastic while still allowing the user to see their hearing instruments. DryBoost UV has double protection switches in the lid to ensure the cycle will shut off if the lid is opened.

Conclusion

Today’s sophisticated rechargeable hearing instruments continue to need drying and sanitizing solutions. The introduction of rechargeable battery technology has changed the game for products to provide those services. A new generation of devices was needed, and the DryBoost UV is a prime example of the innovation that can offer all the care hearing instruments need while remaining careful to navigate the constraints of rechargeable batteries.

About Ear Technology Corporation

For almost 25 years, Ear Technology has been the worldwide leader in hearing instrument care under the banner of the Dry & Store family of drying systems. Dr. Daniel Schumaier, an audiologist in practice for 50 years, formed Ear Technology in 1997 to translate innovative ideas into practical applications, products, and solutions for the challenges in hearing healthcare. Ear Technology manufactures and distributes a variety of hearing-related brands and products, including Dry & Store hearing instrument care solutions, AllClean UV-C® headphone sanitizing equipment, TransEar®, a non-surgical remedy for single-sided deafness, the ClikEZ® family of hearing aids, PLAID® and Tweak® personal sound amplifier products, and EarTech TV Audio®. It could be said that Ear Technology’s corporate motto is simply a reflection of Dr. Schumaier’s personal credo, “Innovation with a purpose: helping people hear better every day.SM”