Rather than disposing of batteries after two or three years, we could have recyclable batteries that last for up to nine years, by using high-frequency sound waves to remove rust that inhibits battery performance, says a team of Australian researchers.

Only 10% of used handheld batteries, including for mobile phones, are collected for recycling in Australia, which is low by international standards. The remaining 90% of batteries go to landfill or are disposed of incorrectly, which causes considerable damage to the environment.

The high cost of recycling lithium and other materials from batteries is a major barrier to these items being reused, but the team’s innovation could help to address this challenge.

The team are working with a nanomaterial called MXene, a class of materials they say promises to be an exciting alternative to lithium for batteries in the future.

The majority of mobile phone batteries are not recycled

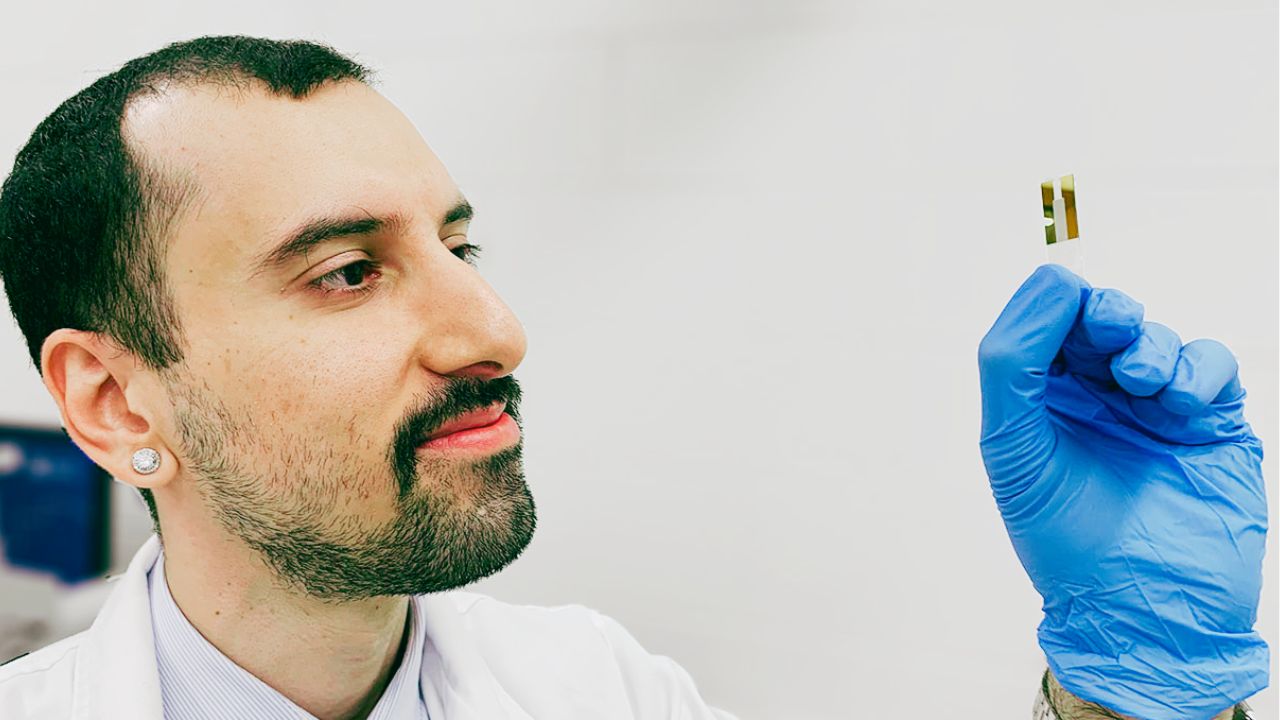

Leslie Yeo, Distinguished Professor of Chemical Engineering and lead senior researcher, said MXene was similar to graphene with high electrical conductivity.

“Unlike graphene, MXenes are highly tailorable and open up a whole range of possible technological applications in the future,” said Yeo from RMIT’s School of Engineering.

The big challenge with using MXene was that it rusted easily, thereby inhibiting electrical conductivity and rendering it unusable, he said.

“To overcome this challenge, we discovered that sound waves at a certain frequency remove rust from MXene, restoring it to close to its original state. The ability to prolong the shelf life of MXene is critical to ensuring its potential to be used for commercially viable electronic parts”

–Leslie Yeo, PhD

The team’s innovation could one day help to revitalize MXene batteries every few years, extending their lifetime by up to three times, says Yeo.

The research is published in Nature Communications.

How it Works

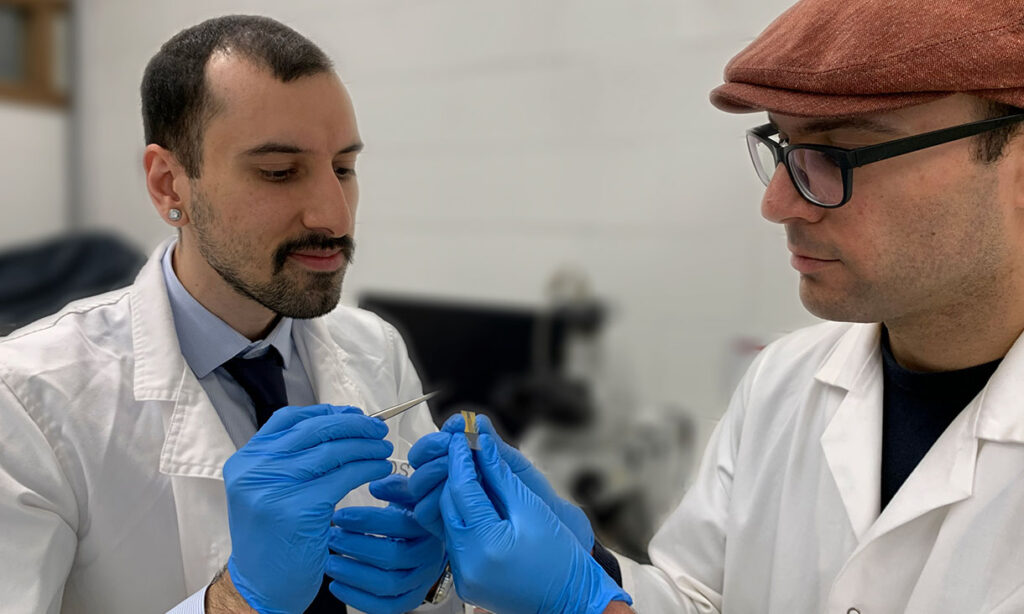

Co-lead author Mr Hossein Alijani, a PhD candidate, said the greatest challenge with using MXene was the rust that formed on its surface in a humid environment or when suspended in watery solutions.

Mr Hossein Alijani, a PhD candidate, and Associate Professor Amgad Rezk with the team’s rust-busting invention. Credit: RMIT University

“Surface oxide, which is rust, is difficult to remove especially on this material, which is much, much thinner than a human hair,” said Alijani from RMIT’s School of Engineering.

“Current methods used to reduce oxidation rely on the chemical coating of the material, which limits the use of the MXene in its native form.

“In this work, we show that exposing an oxidised MXene film to high-frequency vibrations for just a minute removes the rust on the film. This simple procedure allows its electrical and electrochemical performance to be recovered.”

The team says their work to remove rust from MXene opens the door for the nanomaterial to be used in a wide range of applications in energy storage, sensors, wireless transmission and environmental remediation.

**read the full story on the RMIT site here.

Reference:

‘Recovery of oxidized two-dimensional MXenes through high frequency nanoscale electromechanical vibration’ is published in Nature Communications (DOI: 10.1038/s41467-022-34699-3).

Source: RMIT