Much has been written about 3D printing. For those who fit hearing aids, especially custom-molded types, or earmolds, many of us have been told that the shells have been 3D printed. But, what does this actually mean?

What is 3D Printing?

This is known also as desktop fabrication, or additive manufacturing. It is unique in that actual objects are created based on a 3D blueprint design. To many, 3D printing appears to be magic, appearing to build something from essentially nothing – and right before your eyes! Additive manufacturing is the opposite of subtractive manufacturing processes where objects are ‘carved out’ using numerous tools. Additive manufacturing builds an object layer-by-layer without the use of any particular tools and offers much higher levels in shape complexity.

Most 3D printers (3DP) methods use a layer-by-layer process to fabricate objects. The general process for all types of 3D printing is as follows:

- A solid 3D computer model is created from medical imaging data or by computer aided design (CAD).

- The 3D model is sliced into consecutive two-dimensional (2D) slices.

- Each of the 2D slices is then fabricated by a computer-controlled layer-by-layer process.

- Post processing, which may include heating, removing powder, etc.

Is 3D Printing New?

Yes, and no. It was first introduced in 1986, but began to draw serious attention in the 1990s. The first machine having this capability was produced by 3D Systems, and was named the Stereolithographic Apparatus. The reason for this name was because it used stereolithography as the process for printing 3D models.

So, What is Stereolithography?

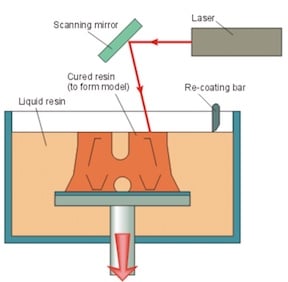

Stereolithography (SLA or SL; also known as Stereolithography apparatus, optical fabrication, photo-solidification, or resin printing) is a form of 3D printing technology used to create models, prototypes, patterns, and production parts in a layer-by-layer fashion using photopolymerization. Photopolymerization is a process by which light causes chains of molecules to link, forming polymers. The polymers then make up the body of a three-dimensional solid (Wikipedia, 2015). The object is manufactured layer by layer, curing the part on each level. When the build is complete, the platform raises above the vat, draining the excess resin away from the part. The process of stereolithography is illustrated in Figure 1, and a video showing the process can be viewed at this link.

Figure 1. Stereolithography employs an ultra-violet laser beam to cure liquid photo polymer in layers. A platform starts one layer depth below the surface of the polymer material and the laser cures the first layer based on thin data slices of the object from a computer. The platform is lowered by one-layer depth and the next layer is cured. The process is repeated until the object is completed. This image shows the top down process, but the build can be reversed, pushing the product up and out of the resin, or bottom up process. In the latter procedure, the laser and mirror are placed below, and not above.

As mentioned previously, 3D printing technology falls within the boundaries of additive manufacturing, which is the opposite of subtractive manufacturing processes where objects are ‘carved out’ using numerous tools. The former, on the other hand, builds the object layer-by-layer without the use of any particular tools. This enables designers to devise even the most complex of designs without having to worry about how they will actually be created; 3D printers can generally print out complex designs with no problems at all.

Different 3D Printing Processes

The term 3D printing technically refers to the development of any object that is made from the ground up. Different processes are used to help accomplish this job, and some of these will be described in that which follows. However, regardless of the process used, the concept behind the creation of objects using 3D printing technology remains the same. The production of a 3D model starts from using a computer-aided design (CAD) software to set up the SL machine. It is from this point on that the actual process used to create the physical object varies.

Four different types of 3D printing processes likely to be encountered are:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM)

- Multi-Jet Modeling (MJM)

3D printing will be continued on the next post, in which the different types of 3D printing will be explained.

Featured image is from file:///Users/waynejstaab/Desktop/3D%20printing/Stereolithography%201.webarchive.

Reference

Wikipedia. Stereolithography. (2015). https://en.wikipedia.org/wiki/Stereolithography.