In researching vintage hearing aid batteries, occasional references are made to the power supplies (batteries) used. However, for most individuals, never having been exposed to out-of-date hearing aids, there is little reason to expect to know what some of the sizes and types were.

This post will review some of the commonly-used batteries and cells at the time, but which are not generally found today. This is a continuation of an historical overview of hearing aids in the earlier vacuum tube era. Considerable text explains the early hearing aids, but not much is available identifying the power supplies used. That is one purpose of this post.

Much credit for the development of smaller hearing aids that could be head-worn, has been attributed to the development of the transistor, over vacuum tubes, which required only a single battery and lower voltage. However, battery companies were always looking to reduce the size and efficiency of their products, including those for hearing aids.

Companies that produced batteries for hearing aids in the early 1950s were National Carbon Co. (Union Carbide), P.R. Mallory and Co., Ray-O-Vac Co., General Dry Batteries, and Burgess Battery Co. To the best of my knowledge, there are only three major companies remaining that manufacture hearing aid batteries.

Vacuum Tube Hearing Aid Batteries

Vacuum tube hearing aids required two batteries, a 1.5 volt “A” battery that powered the vacuum tube filaments, and a higher voltage “B” battery to power the plate circuit to amplify the sound. A few very early “A” batteries were reported to be 3 volts, but the most common, and that which was last used for vacuum tube hearing aids was 1.5 volts (not the 1.4 volt batteries that many are familiar with and which were used with transistor hearing aids). Some very early vacuum tube hearing aids used “B” batteries as high as 90 volts. “A” batteries were used at a rate of approximately 2 or 3 times greater than “B” batteries.

Early vacuum tube hearing aids consisted of a two-pack (or multi-pack) arrangement; one pack for the hearing aid (microphone and amplifier), and the other for the two batteries.

“B” Batteries

Figure 1. Beltone Monopac body-worn hearing aid (1944) – left image. This instrument captured all the hearing aid components into one case, with the exception of the receiver which delivered the signal via a cord to the ear. The monopac allowed for the user to carry one package, rather than two. Previous hearing aids had a separate pack for the batteries, and another for the hearing aid (right image).

Technology that permitted making better and smaller vacuum tubes led to size and power reduction. This size reduction led to the monopac body-worn hearing aids, where the microphone, amplifier, and power supply were all housed within the same hearing aid case (Figure 1).

The reduction in vacuum tube size permitted a similar reduction in battery voltage needs, therefore leading to smaller battery sizes. As an example, the first vacuum tube hearing aids mostly required at least 45 volts for the “B” battery. This later dropped to 30 volts, to 22.5 volts, and then to 15 volts. Examples of some of the earlier “B” batteries, along with their identification and voltage are shown in Figure 2. Once the transistor came into use, and/or when mercury replaced carbon-zinc as the active ingredient in batteries, button-type cells began to emerge. Unlike today, during the 1940s, 1950s, and even into the 1960s, hearing aid companies often had special sizes and shapes for batteries used in their products. In reviewing hearing aid batteries during that time period, at least 60 different battery sizes and shapes were used. Although some were interchangeable, many were not.

Figure 2. Size reductions in the hearing aid “B” battery over time. These reductions coincided with improvements in battery technology and with the reduction in size of the vacuum tubes used in the hearing aids. The battery numbers below each of the menu categories have the same voltages as shown above the batteries, but often had different shapes and contacts.

“A” Batteries

The “A” battery saw changes in its size as well, as shown in Figure 3. These changes consisted primarily in size reduction, with essentially all being of 1.5 volts. Both the button-cell type on the right and those on the left were used during the same time frame. Just as with “B” batteries, a number of different designations existed for the “A” battery. Just a few of these included: 1035, Z-1PL, RM-4, RM-3, RM-1, Z-225, RG-1, RG-3, 1015E, 1016E, M10H, No. Z, Z-1M, M-910H. The size and shape of the “A” battery was often determined by the design configuration of the hearing aid.

Figure 3. “A” battery size and shape examples used with vacuum tube hearing aids. Some were a button-type cell, as shown on the right. A 2017 behind-the-ear hearing aid is shown on the extreme right to provide a reference as to sizes. These are all 1.5 volt batteries used for vacuum tube hearing aids, not the 1.4 volt batteries used later in hearing aids using transistor circuitry.

Only partial transition occurred from taking the “A” battery from paper-wrapped to metal-cased button cells. Figure 4 shows the major “A” battery button cells that were used in vacuum tube hearing aids. Those shown were manufactured by P.R. Mallory Co. of North Tarrytown, NY. They produced the Mallory RM-4, Mallory RM-3, and the Mallory RM-1. All three are 1.5 volts. These were used in vacuum tube hearing aids in the late 1940s and early 1950s. Following the introduction of transistor hearing aids, the RM-1 was sometimes used as the power supply for the hearing aid.

Figure 4. Mallory RM button batteries. These were all 1.5 volts and were used as the “A” battery in many hearing aids in the late 1940s and early 1950s. The RM-4 was the largest button battery made for hearing aid use. It weighed 1.6 oz. (45 grams) and measured 30 mm in diameter and had a height of 17 mm. The RM-3 was 25 mm in diameter and had a height of 16 mm. It weighed 1 oz. (30 grams). The RM-1 measured 15.5 mm in diameter and had a height of 16 mm. It weighed 0.4 oz. (10 grams). It is not clear if a RM-2 existed for hearing aids. A very small hole on the positive side of the RM-4 and RM-3 acted as a valve to relieve excess pressure that could be built up when the battery was being used. The bottom images represent the underside of the batteries shown on the top section.

Button Batteries

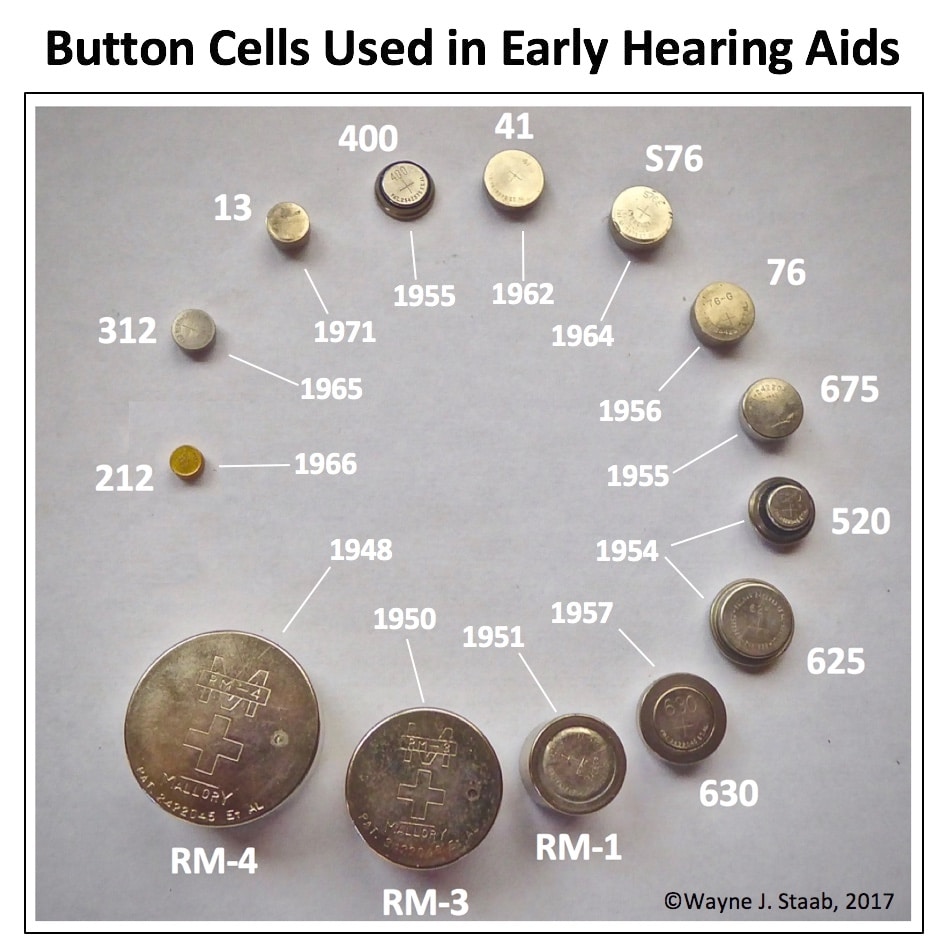

Button batteries (cells) came into extensive use with the introduction of mercury as an active ingredient in hearing aid batteries. They started with the “A” batteries introduced by Mallory, but transitioned to the single power source following the wide use of transistors in hearing aids. Shapes and designations of just some of these are shown in Figure 5. In some cases, button batteries were stacked, or doubled up into a single package, as shown in Figure 6. That package consists of two RG-1 (RM-1) batteries soldered together and covered with paper to represent a single battery. Some hearing aids just put two of these back-to-back in the same battery compartment slot.

Figure 5. Shapes and size reductions in button cells used in hearing aids, with an attempt to show when they started being used in hearing aids. This is not a complete listing, but only features the most common. The three largest (RM-4, RM-3, and RM-1) are Mallory “A” button cells. To the right of these three “A” batteries, and curling around are the single power supply cells used following wide-spread user of transistors in hearing aids. These replaced both the “A” and “B” batteries. As single power supply cells, they no longer carried the designation of “B” batteries. None of these were zinc-air cells.

Figure 6. This Zenith ZB-1 (a guess based on the inability to determine what might have been printed in the space of the paper split) battery consists of two RG-1 (General Battery Co.) batteries soldered together and covered with paper to serve as a single battery. The voltage is 2.6.

A following post will show how some of these batteries actually fit inside the hearing aids.

Ahh yes, I unfortunately remember most of these. Some of the very old aids would come in as a contribution.

Thanks for these articles,

Dick