Personnel who dispense hearing aids often listen to them using some kind of listening device to checke if an aid is functioning, how it sounds, to check for different programmed environmental settings, or for any number of other reasons. A representative sample of commonly-used devices to listen to hearing aids is shown in Figure 1. A number of hearing aid listening devices look and operate in a similar manner.

Figure 1. Sample systems used for listening to hearing aids by hearing professionals. (A), (B), and (C) are yokes with arms that go to each ear. The hearing aid is connected to a flexible tube attached to the yoke where the two arms meet. Listening system (D) consists of a hearing aid connected by a tubing length to a personal earmold to the ear of the listener. This generally goes to a single ear.

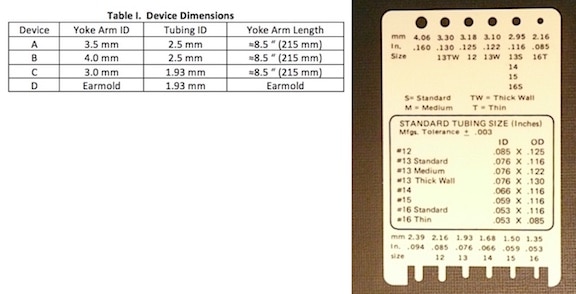

Differences exist between the systems relative to yoke arm inside diameters (ID) and the diameter of tubing connecting the yoke to the hearing aid as shown in Table I. The length of the tube connecting the hearing aid to the listening device also varies. For this study, two lengths were used: 1) 3” (76.2 mm) and 2) 10” (254 mm). It should be noted that the yoke listening systems have, in fact, a much longer listening tube system because of the added length of the yoke arms. Tubing IDs were measured using the tubing guide in Figure 2, except for those larger than 2.39 mm, where a caliper was used.

Figure 2. Hearing aid tubing guide. The holes at the top are used to determine the outside diameter (OD) of the tubing based on the size hole the tubing fits. The tips at the bottom are used to determine the inside diameter (ID) of the tubing based on the tip size the tubing fits over without extending the tubing ID.

What Are They Thinking?

Anyone skilled in the art would know that what they hear through such attachments to the hearing aid does not represent the performance of the hearing aid. It has been known for years that tubing length, internal diameter, wall thickness, and connections affect the hearing aid response. Still, such listening devices continue to be used daily, by perhaps several thousand hearing professionals. The question is, what do they think they are listening to?

What Are They Hearing?

To determine what is being delivered through such listening devices, this author decided to conduct a short test. Three different listening yoke brands and one earmold were connected to a hearing aid (as shown in Figure 1) with different lengths of tubing connecting the yoke or earmold to the hearing aid. Tubing lengths of 3 and 10 inches were attached to the yokes and earmold using a snap-in B adapter.

Figure 3. Flat and hi-frequency responses programmed into the same hearing aid on two different settings, as measured in a 2cc coupler.

The hearing aid used was a RIC (receiver-in-canal) programmed to two responses: 1) a relatively flat frequency response, and 2) a high-frequency response (Figure 3). The hearing aids were attached to the tubing by inserting the speaker outlet tube into the tubing provided by the different devices. Two yoke devices used grey tubing with an inside diameter (ID) of 2.5 mm, and one used #13 tubing (ID=1.93 mm), as did the earmold connection.

Connections to the hearing aid by the two units using #13 tubing allowed for a good friction fit with the RIC speaker (without tip) to eliminate sound leakage (Figure 4a). The larger diameter tube devices required a reduction and sealing process (Figure 4b). The earmold was sealed into the 2cc coupler with putty (Figure 4c).

Figure 4. Hearing aid speaker connection to listening systems. In (a), the speaker tip friction fits into the #13 tubing without sound leakage. This arrangement was used for the earmold connection and for the listening yoke (C). The larger grey tube used with the other two yoked listening systems (A) and (B) required reduction to match the speaker sound bore nub to the larger diameter listening tube as shown in (b). The earmold was puttied to the 2cc coupler as in (c).

Measurement

Figure 5. Setup in a hearing aid analyzer test box for measurement of listening tube performance. One of the ear tips was sealed to the 2cc coupler, while the other was plugged. The length of the tube connecting the hearing aid to the listening yoke or to an earmold was adjusted to meet the measurement length required for the comparison.

Measurement was made using a Frye Electronics 8000 Hearing Aid Analyzer, with one of the listening yoke’s ear tubes putty-sealed to a 2cc coupler. The other ear tube was sealed (Figure 5). For the earmold connection, the earmold was putty-sealed to the 2cc coupler. (Figure 4c).

Results

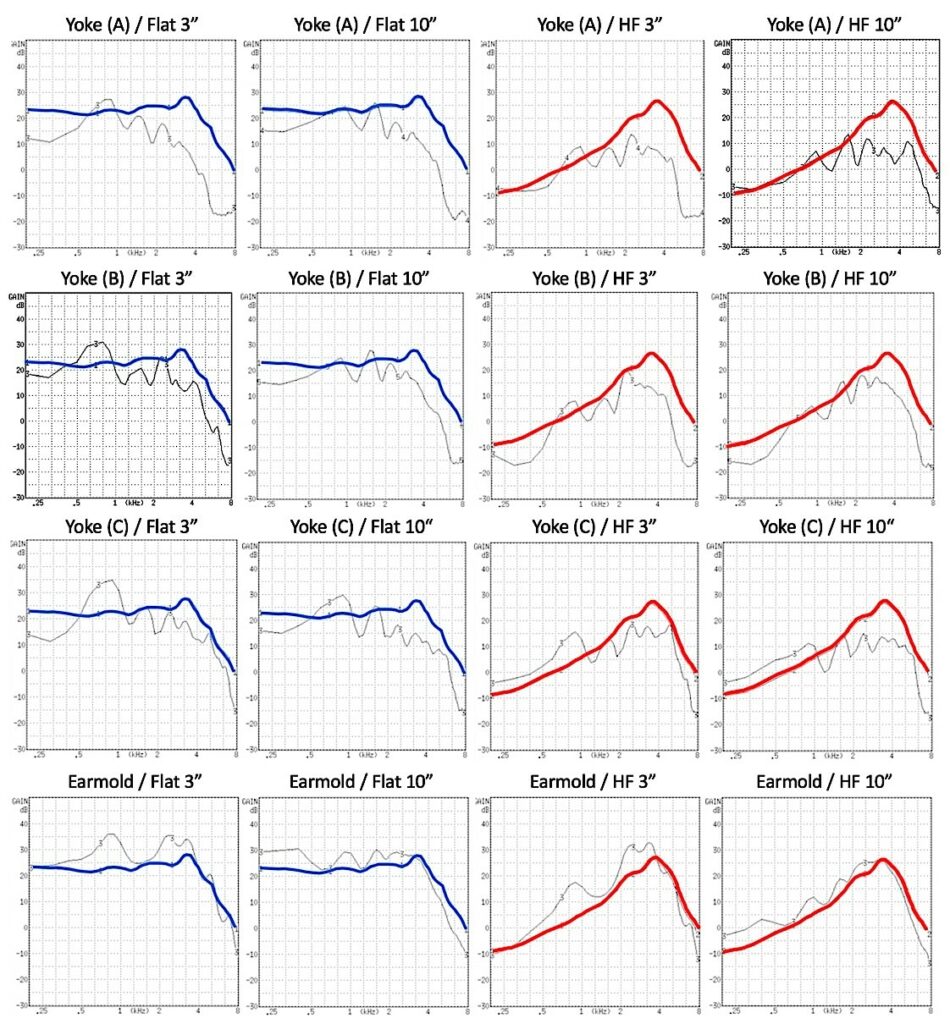

Comparisons of measured response results for the 3” and 10” tubing for the flat and high-frequency responses are shown in Figure 6. The graphs are self-explanatory, and as a result, there is no need to explain each of the graphs separately. Suffice it to say that none of the measured results as measured through the listening devices evaluated here is close to the 2cc coupler measurements. This was expected.

Figure 6. Measured responses for a sampling of the different devices commonly used to listen to hearing aids by hearing professionals. Response comparisons for 3” and 10” of tubing for the flat programmed response are shown in blue. Response comparisons for 3” and 10” for the high-frequency programmed response are shown in red. The measured response is in the light gray color. Yoke and earmold designations are indicated in Figure 1.

Comments

Because none of the listening devices approximates that of the 2cc coupler response, it is unclear how a hearing professional can determine if the hearing aid is functioning properly, aside from it functioning as a dead hearing aid, as a wildly distorted product, or if it is providing some amplification, regardless of how good.

Based on acoustics, a hearing professional should know that tubing resonances, based on length and diameter of the plumbing, lead to the multiple peaks and valleys recorded. Harmonics are easily seen. Realize also that these were smoothed responses shown in Figure 7. It is too embarrassing to show the unsmoothed (actual) responses.

There is no excuse for a hearing professional to make any judgments about the actual performance of a hearing aid when listening to it through any of the systems shown. Other similar devices would suffer the same non-usable information.

Recommendations

- Measure the hearing aid’s performance using an appropriate hearing aid testing system.

- Listen to the hearing aids as does the client. Put them on and listen to them! It has to be assumed that all dispensers have disinfectant means, and with most of today’s hearing aids, one could also easily replace the tips with a new one or one of their own of similar design.

- Do not make judgments about a hearing aid performance by listening to it through listening devices as described in this brief comparison.

I’m starting to lose my hearing, and I’m not sure what to do. It makes sense that getting a hearing aid might be what I need! I’ll start by talking to a professional to test my hearing. They would be able to ensure that I take care of everything properly.