We know that most electronic devices, including hearing aids, are tested to be moisture resistant, some are even said to be “waterproof”. Hearing care practices in high humidity locations, routinely deal with water, sweat and other common hearing aid repairs. These issues have long been problems with both hearing aids and cochlear implant processors.

Practitioners realize that hearing aids are delicate electronic devices with high-tech circuit boards and microelectronics that are particularly prone to the corrosive effects of humidity and perspiration (Hay, 2020). Due to Nano coating, better case sealing, and other manufacturing innovations, there has been significant progress in moisture reduction greatly increasing the reliability of hearing devices. Waterproofing, however, has escaped most products by virtually all hearing device manufacturers.

Thus, moisture is still a major issue in the reliability of hearing aids and cochlear implant processors.

Ingress Protection Code (IP) Ratings

While most manufacturers of hearing devices state that their products have a high IP rating, most providers only have a cursory understanding of what that really means. IP stands for Ingress Protection Code, sometimes called the International Protection Code that classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and especially, water.

This standard is published by the International Electrotechnical Commission (IEC). Ingress Protection or IP ratings classify the level of protection that the casing of a hearing instrument provides against solids and liquids entering and damaging the device. Figure 1 presents the list of the various IP ratings.

IP ratings are usually made up of two digits, the first denoting resistance to solids and the second to liquids. Hearing aids and other products receive a two-digit IP rating from the IEC. For hearing instruments, these ratings classify the level of protection that the hearing instrument case provides against solids and liquids entering and damaging the electronics within the device. According to the rating scheme, the first digit rates the degree of protection against debris, such as dust or sand, and is rated on a scale of 1-7. The second digit is rated on a scale from 1-9, that indicates how resistant the electrical device, such as hearing aids are to moisture.

Hay (2020) and Bailey (2020) indicate that while IP ratings can be a helpful guide, these ratings are assigned in laboratory conditions with “clean” water rather than sweat or rain. Further, IP ratings are not certified for various uses and may not reflect the cases’ protection for specific intended uses such as being body worn. Therefore, while a high IP rating is desirable, it does not guarantee moisture protection in the real world.

In the old days of amplification, behind the ear hearing aids were “sweated out” quite often and a significant reduction in these situations were offered by the development of nano-scale polymer coatings. These liquid-repellent nano-coating technologies generally protect consumer electronic devices against damage from water and sweat and improve performance reliability for the circuits, microphone and receivers of hearing aids which are at high risk of liquid and debris damage.

In the old days of amplification, behind the ear hearing aids were “sweated out” quite often and a significant reduction in these situations were offered by the development of nano-scale polymer coatings. These liquid-repellent nano-coating technologies generally protect consumer electronic devices against damage from water and sweat and improve performance reliability for the circuits, microphone and receivers of hearing aids which are at high risk of liquid and debris damage.

The combination of manufacturing techniques, sealing of the products and nanocoating have netted most models of today’s hearing instruments a rating of “IP68” on the Ingress Protection rating scale. The “6” in the IP rating indicates excellent resistance to solid contaminants (“dust-tight, no ingress of dust over two-to-eight hours”), and the “8” indicating excellent water resistance (“resists periods of immersion under water”, generally up to 3 meters, or 9.8 ft).

IP ratings and nanocoating have made hearing instruments substantially more reliable than those of the 1970s and 1980s. However, completely waterproof products are very scarce and, no matter what a manufacturer says about their IP rating, there are still very real and pragmatic problems with moisture in everyday use of these products.

Although the reliability is better than the past, recent research by Redux (2019) revealed that 98% of today’s IP 68, nano coated hearing aids from virtually all manufacturers have some amount of moisture present. Even with these innovations in moisture control, hearing aids operate in a very difficult environment:

- Hearing aids spend hours surrounded by the skin which releases moisture (sweat) to control body temperature.

- The effects of perspiration may be greater due to exercise, certain medications, or other underlying health conditions.

- In some environments such as coastal cities, island visits, cruises and other such situations where humidity exists as a vapor, this moisture can pass through traditionally water-resistant barriers.

- Hearing aids get wet in cold weather. Condensation due to fast temperature change from inside/outside temperatures may create a layer of moisture in and on hearing aids.

- Drizzle and rain are a constant threat to hearing aids.

The Redux system is innovative moisture removal technology that substantially reduces the frustration by providers, patients and manufacturers that introduces a scientific process used by cell phone repair shops for many years. The use of this simple system significantly reduces provider labor, hearing device repairs, and down time for patients while increasing revenue for the practice.

Benefits of a Dry Hearing Aid

Modern hearing instruments are full of digital circuits and components and it only takes an exceedingly small amount of moisture to negatively impact sound quality. In fact, audiometric testing by Redux (2019) found that only 0.5 microliters of moisture were enough to create a 30-dB reduction in hearing aid volume. To a hearing-impaired person used to devices performing at a certain level, that 30 dB can be a significant detriment.

Additionally, manufacturers report that a large percentage of returns and repairs are due to moisture damage. This represents thousands of hearing aids either returned or sent for repair causing the individual to be without their devices during the hotter and more humid summer months. Thus, dryer hearing aids result in fewer returns or repairs and significantly less follow up for the provider and staff.

Imagine the Benefits?

Steve Jobs once said, “Every once in a while, a revolutionary product comes along that changes everything.” Of course, he was discussing the introduction of the iPad but imagine him holding a Redux machine, a true 21st Century invention that will be just as revolutionary to hearing aids and hearing care as the iPad was to computers. Such revolutions in hearing care are those that make significant differences to patients while providing a revenue stream to practices.

Steve Jobs once said, “Every once in a while, a revolutionary product comes along that changes everything.” Of course, he was discussing the introduction of the iPad but imagine him holding a Redux machine, a true 21st Century invention that will be just as revolutionary to hearing aids and hearing care as the iPad was to computers. Such revolutions in hearing care are those that make significant differences to patients while providing a revenue stream to practices.

Over the years, major differences that meet these two criteria have been digital products, programmability, the use of memories, miniaturization, Bluetooth cellphone and television connectivity.

Like some of these technologies, Redux is one of those “game changers”, a technology from another industry that is making a substantial difference for patients that use hearing aids and cochlear implants and, simultaneously, provide another revenue stream for practices.

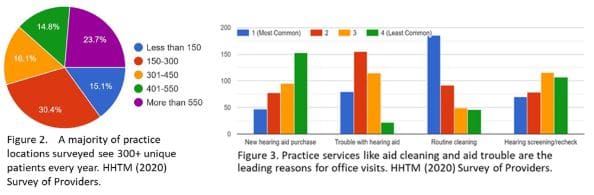

In a recent study from 372 hearing care professionals, HHTM (2020) found that there were certain facts about independent hearing healthcare practice that should be considered when adding any product or service into the clinical mix.

About 75.9% of the clinics surveyed will have up to 550 unique patients, those that are seen in the clinic for the first-time every year (Figure 2). Sometimes these are walk-in patients or consumers with emergent problems. While they may not be considering new products, they may need to have their current instruments repaired or adjusted so that they can continue their use until they are ready to update with new instruments. Existing patients, that practitioners have seen for many years are commonly visiting the clinic every 2-4 months (Figure 3).

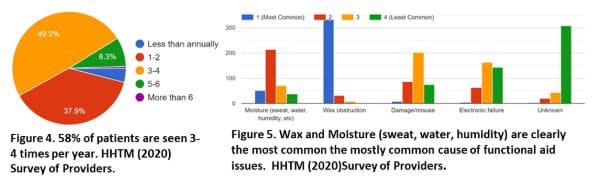

According to the survey, 58% of providers see their existing patients 3-4 times per year (Figure 4). Common problems patients experience with their hearing devices those that simply require cleaning or have malfunctioned due to wax, moisture from sweat, water or humidity (Figure 5).

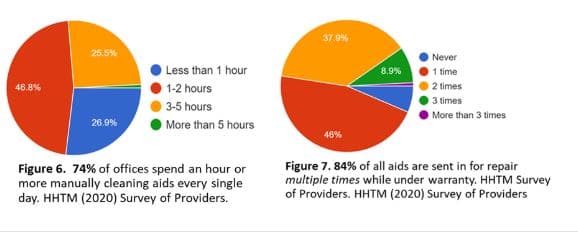

Consider that 74% of providers spend at least 1 hour per day cleaning hearing aids (Figure 6). If these activities could be reduced or eliminated, it could allow for other more profitable procedures to be scheduled. A high percentage, 84%, of hearing aids dispensed are sent in for repair multiple times for various reasons while under warranty (Figure 7).

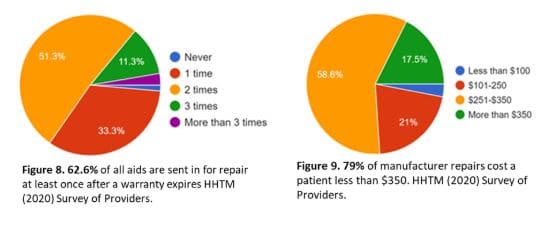

This causes the patients to be without amplification during this time or requires the use of loaner hearing aids. The survey found that 62.6% of devices are sent for repair at least twice during the out of warranty life cycle (Figure 8). Most of these costs are less than $350 and usually come back from repair with either a 6 month or 1-year warranty depending on the repair laboratory (Figure 9).

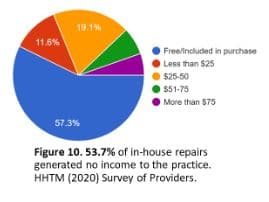

If the devices could be repaired in house rather than being sent to an outside source, the costs to the consumer were significantly less. However, instruments that were repaired in house including those that were out of warranty did not generate income 53.7% of the time (Figure 10).

If the devices could be repaired in house rather than being sent to an outside source, the costs to the consumer were significantly less. However, instruments that were repaired in house including those that were out of warranty did not generate income 53.7% of the time (Figure 10).

But what If …. The hearing device could be fixed in the clinic and returned to service in less than 15 minutes for a fee in the office? This service would save the patient $250-350 for a repair from a third-party service.

The Redux system may be the answer to getting instruments back into operation without the down time and providing an income to the clinic.

What Is the Redux System?

As a practitioner, my first impression was that Redux was simply another home drying product for patients to purchase and dry their hearing aids at home in humid climates or for those that have moisture problems. First impressions are, of course, sometimes inaccurate, especially for a technology that is new to hearing care. Rather than a mere home hearing aid dryer for everyday use, the Redux system is a true repair service that has been used in cell phone and computer repair shops for quite some time.

Redux drying technology already has a proven history within the wireless communication industry, focusing on wet consumer electronic devices such as cell phones and tablets. Redux drying hardware can currently found in over 2,000 cell phone retail locations nationwide. To date, approximately two million people have enrolled in a membership program with Redux to protect their cellular equipment from moisture damage and data loss.

Redux drying technology already has a proven history within the wireless communication industry, focusing on wet consumer electronic devices such as cell phones and tablets. Redux drying hardware can currently found in over 2,000 cell phone retail locations nationwide. To date, approximately two million people have enrolled in a membership program with Redux to protect their cellular equipment from moisture damage and data loss.

Co-founded by the former head of R&D at Songbird, Redux quickly adapted this innovative drying system to treat hearing aids, implants and hearable electronics. The technology was field tested by hospitals and hearing care professionals across North America.

Based upon that third party reporting, Redux partners found that 76% of the time the use the vacuum drying system rectified many routine hearing aid repair problems, such as cerumen in the receiver, moisture limited devices or receivers, and other simple issues of debris that often require manufacturer repairs or receiver replacement.

How Does Redux Work?

Redux vacuum technology does not create a vacuum in the traditional sense, such as exhausting air from an enclosed space. It simply lowers the atmospheric pressure in the chamber so that water boils out of the device at a lower temperature.

The basic science is simple. At sea level water boils at 212 degrees, but at lower atmospheric pressures water boils at a much lower temperature, well under the 212-degree mark.

The Redux vacuum system extracts air pressure from the chamber, lowering the atmospheric pressure to below body temperature allowing the moisture to boil out at a lower temperature. Using this principle, the Redux system has an automated process:

- Redux vacuum technology reduces atmospheric pressure in the chamber, thereby lowering the evaporation or boiling point of water from ~212F to below body temperature of ~98F.

- Redux applies heat within the chamber to evaporate moisture at this safe temperature.

- Redux replaces the wet air with fresh dry air and then begins creating a new vacuum to repeat the process over again and the system will repeat the three-step process of air pressure reduction/heat/fresh air until the built-in humidity (moisture) sensor determines when all moisture has been removed.

- For most hearing devices, this entire moisture extraction process takes about 12 minutes with the simple push of a button.

- Next, the Redux verifies the amount of moisture that was removed visually and with a printout for either the patient or provider’s records.

- Recent studies by Redux have documented that this drying process using lower atmospheric pressure does not create any change in rechargeable battery life.

How to Incorporate Redux into a Practice

Hearing health care practice revenues are down, economic uncertainty prevails, and safety is of concern to prospective purchasers of hearing products. Clinics should seriously consider leasing the Redux system at $225 per month (negotiable based on number of locations and terms of service). It is a meager investment for high return in the repair of hearing devices that would ordinarily be sent to the manufacturer or a repair laboratory.

Recall that most of the troubleshooting and in-house repair is conducted for no income and, if repair is necessary, there is down time and a significant cost if the device is out of warranty.

Many patients have moisture issues consistently. These higher risk individuals could find significant value in a yearly “subscription” option that allows them use of the Redux service whenever required. Other patients, however, will not want to pay up front for services that may or may not be necessary for their situation. For these consumers, a fee for service option is their preferred method.

A practice can offer any combination of these options by customizing a plan and pricing specific to each patient’s needs.

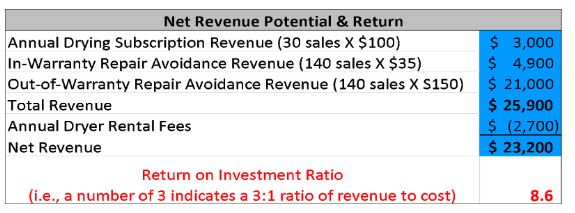

Yearly Program

Annual treatment program for $100 per year (again, practices can price services how they see fit), allowing those higher moisture risk patients unlimited access to the Redux system.

Fee for Service (In Warranty)

For patients that occasionally deal with moisture issue or just have occasional accidents leading to wet aids, paying a lower $35 one-time fee to have all moisture removed is appealing. This can also warranty return inconveniences like being without the aid while it’s sent for repair

Fee for Service (Out of Warranty)

The value of a successful Redux treatment is significantly higher to a patient out of warranty due to higher costs of repair. Practices can charge $150, and if drying ends up not being the issue then the expense can be credited toward the cost of the return. There is no risk to the patient.

This calculator provides an example of revenue potential for a 300-patient practice using a combination of these service offerings. Note that the revenue opportunity increases with patient count while Redux system cost remains the same.

Where Do We Go from Here?

Redux works on a leasing system which allows them to control updates in the technology, software support, and the in-office hardware. Redux is ready to send hardware to your office for trial at no cost. They would like providers to see first-hand how beneficial it can be to the practice. Here’s how the Redux will work to get a unit the practice:

- Redux will send the practice a system to try for 1 month and provide training on how to use the device and incorporate it into practice.

- If, for any reason, the provider does not see the benefit to their patients and/or gain financial benefit from its use, return it to Redux for absolutely no cost.

I see this as an innovative approach to improving the hearing health of patients and be a technological restart for the practice as summer approaches.

References:

- Bailey, A. (2020). Best waterproof hearing aids for 2020. Hearing Tracker, Retrieved May 28, 2020.

- Flexfire (2020). IP Chart. Flexfire LED, Inc, Costa Mesa, CA, retrieved May31, 2020.

- Hay, M. (2020. How to Protect Your Hearing Aids from Moisture. Hearing Tracker, Retrieved May 28, 2020.

- HHTM (2020). Survey on hearing aid Repairs. Hearing Health and Technology Matters. Retrieved May 28, 2020.

- Redux (2019). Measurements of moisture removed from more than 750 hearing aids. Redux, Inc, Carmel, Indiana.