By Mike Housholder, VP of Marketing and Business Development at xMEMS

The history of hearing aids dates back centuries, but the first recognizable and functional electric hearing aid can be traced to the late 19th century when, in 1891, a French engineer named Ernest Mercadier created a pioneering device known as the “Akouphone.”

Consisting of a carbon microphone, which was connected to an earpiece by a cable, the microphone picked up sound vibrations and converted them into electrical signals. These signals were then amplified and transmitted to the user’s ear through the earpiece.

Most hearing aids today utilize BA speakers

Over subsequent decades, technological developments led to great enhancements in sound quality and a remarkable reduction in the size of hearing aids. Integral to this process has been the continual advancement of miniature microphones and speakers, which ushered in an era of discreet, high-performance hearing aids.

Currently, most hearing aids use balanced armature (BA) speakers, which manufacturers traditionally favor because of their small, compact size and efficiency/low power consumption since medical-grade hearing aids are expected to last the wearer’s entire day.

Balanced armature speakers also provide high-quality audio in a narrow bandwidth — an ideal functionality for voice amplification since the human voice only operates within a narrow frequency range.

But now, with a new category of over-the-counter (OTC) hearing aids emerging and devices evolving from purely medical products into true lifestyle devices with “earbud-like” designs, an alternate speaker architecture is needed to ensure quality and reliability while also achieving a higher level of audio performance.

The multi-purpose earbud style devices are a popular OTC offering. Sony’s CRE-E10 devices, shown above, are one such example.

Transition to Solid-State Silicon

Today, all-silicon MEMS (micro-electromechanical systems) speakers are just beginning to hit the market.

Moving coil speakers, which BA speakers derive from, have been the primary technology for sound reproduction for over a century. It’s a multi-component mechanical assembly consisting of a voice coil, magnet, chassis/frame, paper/plastic diaphragm/cone, dust cap and spider (suspension).

In contrast, MEMS speakers consolidate all these functions into a single piece of silicon, resulting in a monolithic structure to reproduce sound that is inherently more uniform, consistent, reliable and lighter weight, with improved audio resolution. These tiny devices replace the coil and magnet actuation mechanism with a thin-film piezo layer (a layer in the semiconductor wafer) and silicon replaces the paper/plastic diaphragm.

In contrast, MEMS speakers consolidate all these functions into a single piece of silicon, resulting in a monolithic structure to reproduce sound that is inherently more uniform, consistent, reliable and lighter weight, with improved audio resolution. These tiny devices replace the coil and magnet actuation mechanism with a thin-film piezo layer (a layer in the semiconductor wafer) and silicon replaces the paper/plastic diaphragm.

This transition from mechanical to solid-state is far from new. Computer hard drives went from spinning disks to solid-state drives starting in the 1990s.

In the audio space, according to MEMS industry analyst Yole Group, solid-state MEMS microphones commanded just 5 percent of the market in 2007, but by 2022, that share was 72 percent. As solid-state speakers move into production, they could follow a similar trajectory, and here’s why.

Smaller Size, Wider Frequency Response Coverage

Cowell (left) vs. Balanced Armature (right)

The most immediately obvious reason is size. All it takes is one look at a MEMS speaker to see it’s even smaller in total area/size versus a typical balanced armature. Length and width are similar to BA’s, but the key difference is shorter height.

This means MEMS speakers can fit nicely inside any hearing aid form factor, including the most popular Receiver in Canal (RIC) devices.

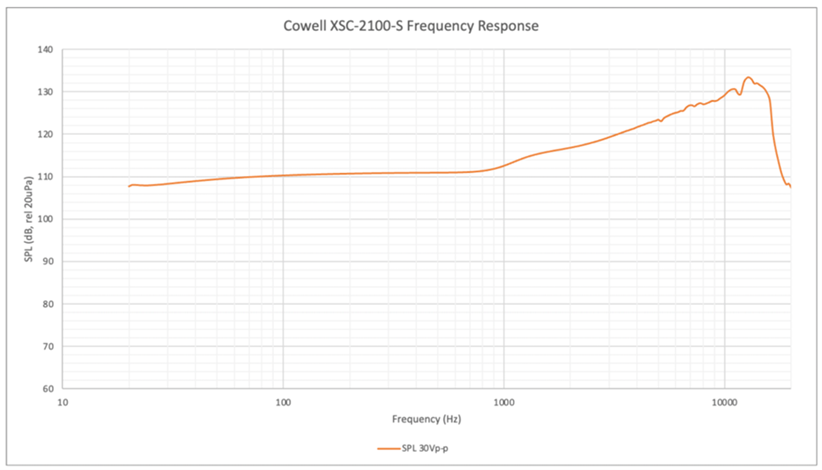

Less obvious is that MEMS speakers can produce the full human hearing frequency range from 20 Hz to 20 kHz. So, not only can your hearing aid amplify voices, but it can also be used for rich, complex media playback—including music, podcasts, movies, etc. This is becoming increasingly important as advanced hearing aids combine the best features of Bluetooth earbuds (media streaming) and hearing instruments (voice amplification).

The reality is current BA speakers are unable to fully deliver on low frequency sound and many don’t produce much output above 8kHz — both the lows and the extended high-frequencies are essential for true media reproduction.

Robust and Consistent

Physically, solid-state MEMS speakers are more robust than BAs because they’re made from one monolithic silicon structure and are more resistant to drops or mechanical shock.

They’re IP58 rated for moisture/dust/particulate resistance, perfect for hearing aid wearers that rely on their devices in varying environments.

Plus, MEMS speakers can be manufactured quickly at large scale thanks to established, high-capacity silicon fabrication plants. Rather than assemble speakers from disparate parts, we can now “etch” them in silicon using standard semiconductor processes and packaging.

With the new OTC initiative, consumer demand for hearing-assistance devices is expected to increase dramatically. MEMS’ high volume manufacturing capacity will be able to support this increased demand where BA suppliers may struggle to keep up.

How about Consumers?

Speaking of consumers, most important for them is that MEMS speakers help create better-sounding, more comfortable hearing aids. The thin-film piezo actuator film is applied in a layer as part of the semiconductor fab process to silicon, which serves as the speaker diaphragm to move air and produce sound.

Speaking of consumers, most important for them is that MEMS speakers help create better-sounding, more comfortable hearing aids. The thin-film piezo actuator film is applied in a layer as part of the semiconductor fab process to silicon, which serves as the speaker diaphragm to move air and produce sound.

It’s the stiffness of silicon that helps deliver higher-quality sound, along with the uniformity and consistency of semiconductor manufacturing.

With no coil to spring into action, and with actuation and diaphragm components created in silicon, solid-state speakers respond instantly to voltage, meaning there’s no muddying or discoloration of the sound caused by resonating parts.

Frequency response is much smoother as well, with MEMS speakers offering a linear response without the resonant peaks and valleys common in many BA devices. A linear frequency response means each frequency is reproduced with equal emphasis, maintaining the intended balance and tonality of the original source. In hearing aids, this results in a more natural, lifelike sound that closely mirrors the wearer’s natural hearing.

MEMS speakers offer a smooth, linear response without the resonant peaks and valleys often present in many BA devices. Source: xMEMS

Aside from sound quality, comfort is usually a top priority for consumers, given they’re supposed to wear their devices all day. Traditional BA’s typically are not vented. So, as the speaker diaphragm pushes air to generate sound, it can pressurize the ear canal leading to long-term discomfort in the eardrum. The speaker diaphragm in MEMS speakers are vented. As it actuates, the vented diaphragm allows any air pressure build-up to escape out the back of the speaker so as to not pressurize the eardrum.

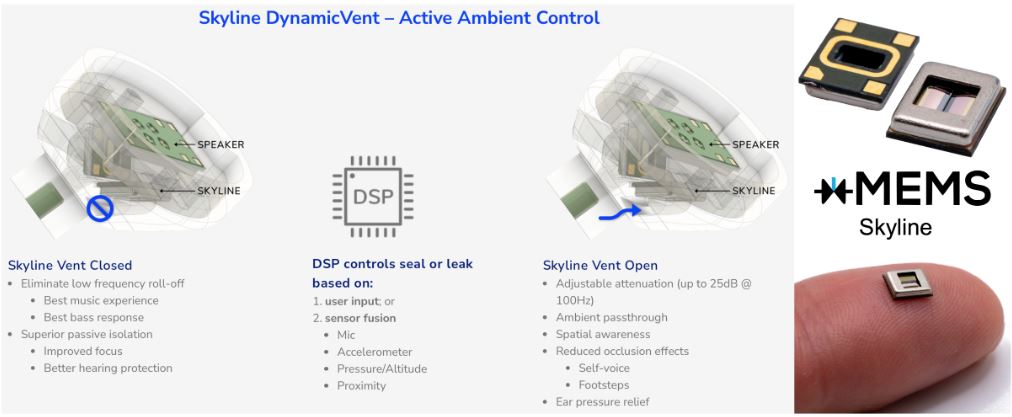

The second comfort challenge with hearing aids is balancing open-fit and closed-fit eartips for managing occlusion effects, i.e. a heightened perception of external sounds, including one’s own voice, breathing, or footsteps.

At xMEMS, we have developed a novel active vent solution for this called Skyline. Skyline is a separate chip using the same piezoMEMS platform as our speakers. The Skyline vent can be opened and closed at whim, making it possible to occlude the ear when preferable, like on an airplane, and leave it open when on a work call. Skyline makes hearing aids more flexible and adaptable to multiple wear/use scenarios.

MEMS speakers show clear benefits for both hearing aid manufacturers and consumers and the technology has a proven track record across other electronics categories.

As consumer adoption of media-centric, Bluetooth-connected hearing assistance devices continues to rise, MEMS speakers are uniquely positioned to meet increased demand, while BA manufacturers may have difficulty keeping up.