Hearing Aid Evolution: Technology and Techniques – Part II

Last week’s post was the first part of a three-part series on the “Evolution of Hearing Aid Technology and Techniques – A Ride Through History.” Last week focused first on factors that drive hearing aid development and then highlighted some of the major developments (primarily hardware) that shaped the changes to hearing aid design. This post will take the ride from power supplies through developments related to hearing aid transducers. As pointed out previously, often the changes seen represent the wheel reinvented.

Power Supply – As the battery goes, so goes the hearing aid

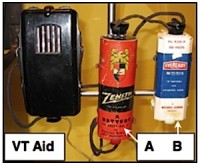

Hearing aid miniaturization has moved hand-in-hand with battery size. It might be said that as the battery goes, so goes the hearing aid. In the early carbon microphone hearing aids, carbon zinc provided the electric potential. Following this, vacuum tube hearing aids used zinc batteries; a 1.5 volt ‘A’ battery for the heater to warm the tube, and a 30-45 volt ‘B’ battery to power the amplifier (remember, vacuum tubes regulated voltage for amplification, which is the reason for the high battery voltage for the ‘B’ battery).

Batteries for carbon and vacuum tube hearing aids came in many sizes and voltages, depending on the hearing aid. As a result, users had to purchase batteries from specific suppliers, so it was not possible to purchase a “generic” hearing aid battery. It was not until WWII that the War Production Board saw the uselessness of different sized batteries (in general), and decreed that only certain size batteries could be manufactured. This related to all batteries, including those used in hearing aids.

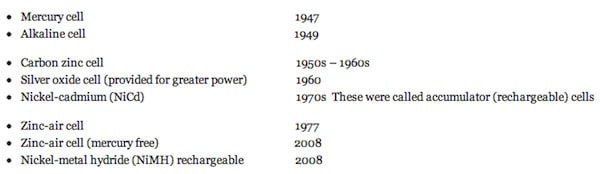

Hearing Aid Power Time Line

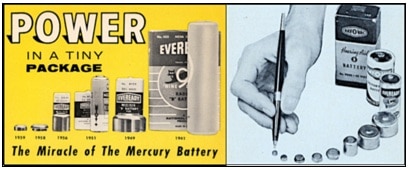

The name of the battery most often defines the depolarizing agent, as is shown here, along with the date of introduction.

- Zinc carbon battery (Lechlanche’ Cell) 1866

- Alkaline battery (Thomas A. Edison) 1901

- Mercury battery – enabled smaller vacuum tube aids 1940

Hearing aid power supplies eventually made the transition from batteries to cells with the transistor amplifier because only a single cell was required since there were no vacuum tubes to heat, and, amplification changed to current regulation rather than voltage regulation. This meant that large voltage batteries were no longer required. As a point of information about batteries and cells, a battery consists of more than a single cell. Today’s hearing aids actually use a cell and not a battery. However, most people follow the traditional choice of “battery” when referring to the power source. Some early vacuum tube batteries coupled individual cells wired together and covered with paper or plastic, to look like a single unit.

Major developments related to hearing aid general use, not necessarily when invented or first used

Rechargeable chemistry can save money when it comes to replacing batteries, but many consider their high self-discharge rate a disadvantage. It is for this reason that most hearing aids that use rechargeable NiMH batteries have multiple sets that are kept fully charged.

Rechargeable chemistry can save money when it comes to replacing batteries, but many consider their high self-discharge rate a disadvantage. It is for this reason that most hearing aids that use rechargeable NiMH batteries have multiple sets that are kept fully charged.

Hearing aid batteries have made the transition from 45 volts (voltage regulators), to 1.35 to 1.45 volts today (regulating current). The power supply is a critical element to hearing aid designers; most often related to size, crimp angle, zinc-air openings, and discharge conditions. Zinc-air cells are the dominant battery used in hearing aids. But, looking toward the future, heat from the human body itself has been speculated as a potential hearing aid power source.

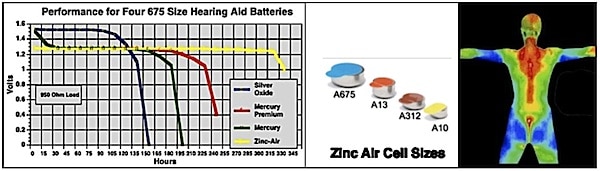

Left to right: hearing aid battery discharge rates for batteries that have been used in modern hearing aids. The Zinc-air cell has the steadiest, and longest performance prior to discharging. Mercury batteries are no longer used in hearing aids. When power is required, it is sometimes necessary to use silver oxide cells – often in hearing aid remote controls where frequent use may not allow the battery to recover fully before the next push button command. The middle image shows the relative size of current hearing aid cells. The right image indicates body heat areas that are already being harvested for some low-power and low-current drain consumer products.

Hearing Aid Transducers

These consist of the microphone and speaker (receiver), both of which have undergone substantial changes.

Microphone – The microphone receives sound and converts it from an acoustical to electrical (or digital) signal.

- Carbon Microphone – This was described in Part I of this series. It was not only a microphone; it also provided the amplification for the hearing aid.

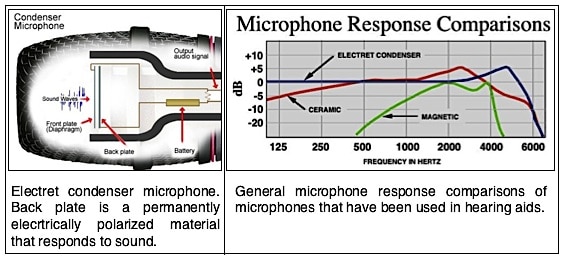

- Crystal Microphone – This microphone was common with vacuum tube hearing aids. Its response was generally high frequency. It was not an ideal microphone because it was relatively fragile, and would lose its sensitivity in hot and humid conditions.

- Magnetic/dynamic Microphone – This microphone was used with transistor amplifier hearing aids. The highly balanced armature magnetic microphone was more compatible with low impedance speakers. Being a smaller-sized microphone, it reduced both the high- and low-frequency response, which was a disadvantage. But, it did provide for greater stability of performance and smaller size (size always being important in the evolution of the hearing aid).

- Ceramic Microphone – This type microphone was free from temperature and humidity problems and had limited use in hearing aids until the FET (field effect transistor) was added into the microphone case, were it acted as a pre-amplifier.

- Electret Condenser Microphone – In reality, this is actually a piece of permanently electrically polarized material that responds to sound. It has two distinct advantages: (1) it has reduced vibration sensitivity, and (2) it results in smaller hearing aids when the FET is added.

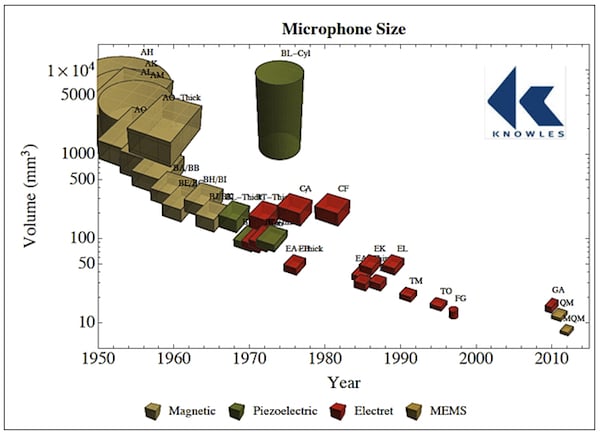

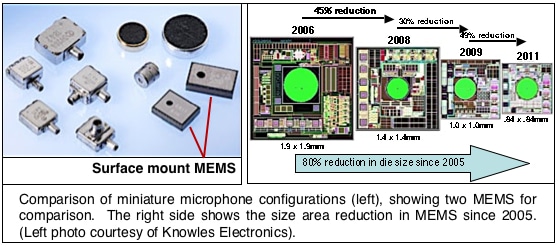

Microphone size (volume) changes through the years that have been used with hearing aids. Courtesy of Knowles Electronics.

- MEMS Microphone – MEMS stands for Micro-Electro-Mechanical System. What this technology does is add mechanical structures to an IC substrate; in this case, it builds the microphone into the silicon, creating a totally different type of microphone. The accompanying image compares traditional hearing aid microphones to surface mounted MEMS. At last report, the MEMS microphone was less subject to vibration and moisture issues, but had a slightly higher noise level.

Receiver/Speaker – This transducer takes the amplified signal and converts it back to an acoustical signal. As with hearing aid microphones, speakers have undergone changes as well.

- Crystal receivers – These operated in reverse fashion from crystal microphones and were used in early carbon and vacuum tube hearing aids.

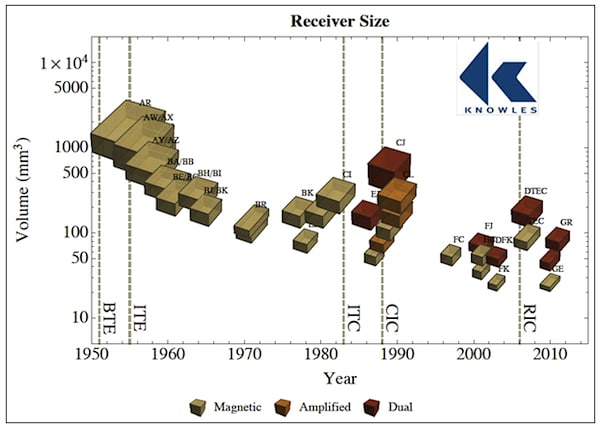

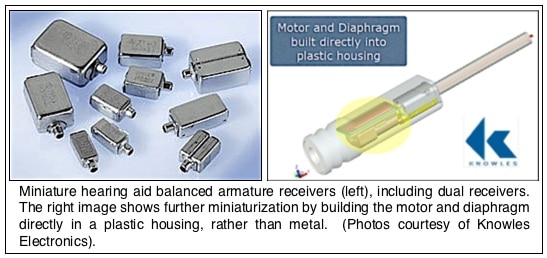

- Balanced Armature Magnetic Receiver – These are the receivers used in hearing aids today. They have been enhanced by what is called the Amplified Class D Integrated Receiver. This improvement allowed the speaker to be further miniaturized.

Hearing aid receiver/speaker size (volume) changes through the years that have been used with hearing aids. Courtesy of Knowles Electronics.

Next week will conclude this post series on the Evolution of Hearing Aids.

I hope you will cover telecoils, orientations, new applications universal for loop technology in the next article.

Cheri:

Your topics will not be covered in the next post, but these are good topics and I think I will work to put an entire post together just on these issues. Thank you for your interest.