Evolution of Hearing Aid Technology and Techniques – A Ride Through History

Factors that Drive Hearing Aid Development

Starting with the first hearing aids developed, and continuing today, three factors have driven hearing aid technology and development. These three factors, in their historical ranking, are:

- Cosmetics

- Technology leading to miniaturization, and

- Packaging

Cosmetics

Patients have always been interested in the most cosmetically appealing hearing aid – translated as “invisible” or “smallest.” This is evident by reviewing hearing aid sales. This means that they are interested in the most inconspicuous hearing aid that can possibly be coupled with the technology at the time. Stories abound about the individual who says, “I don’t care what the hearing aid looks like, as long as it provides the significant listening performance I’m interested in.” But then, when the instrument is presented to the patient, the first thing they ask is, “Yes, it works as expected, but can’t it be made smaller?” All one has to do is look at hearing aids over time to confirm that “smaller” and “invisible” have dominated much of the development. Many patients have not been fitted as well as they could have been because cosmetics, and not performance, drove the sale.

Technology and Miniaturization

Technology, often evidenced by miniaturization of hearing aid components, has complemented the driving force for cosmetics. In other words, improved cosmetics most often has come about because of miniaturization of components. But, technology is not only miniaturization; it also means providing the best sound quality possible using existing developments. And, part of this consists of attempts to mimic human hearing as closely as possible.

Packaging

Packaging involves the design and manufacture of the hearing aid itself. Design goals are to make construction and use of the instrument as simple and straightforward as possible. One has to wonder, however, if some of the current designs have lost their way when it comes to this important factor – perhaps not so much with respect to construction, but conceivably when it comes to consumer use. We have instruments that have multiple functions and accessories – and usually with small controls for the patient to manipulate. This is not always easy when approximately 65% of the people wearing hearing aids are 65 years of age or older. So, remotes are added, which means that now the patient can lose or break two devices rather than one. Developments that enable the hearing aid to make decisions and adjustments for the patient based on the incoming signal are promoted heavily, but they might be questioned. What happens to hearing aid performance when multiple parameters are adjusting at the same time? Do we really know? Could they be interfering with each other, especially as more parameters are being manipulated? The hearing aid circuitry is making decisions based on physical input sound pressure. Unfortunately, actual hearing needs are often based on psychoacoustics, emotion, or patient preference – all of which can change from moment to moment. Self-adjusting hearing aids cannot manage these mood changes.

Major Developments

The development of a hearing aid consists of a series of compromises. A more powerful hearing aid requires a larger power supply and most likely larger transducers as well as other components, leading to a larger physical size of the hearing aid. How many microphones are desired? What about streaming, telecoil, volume control, other user controls, connection options, Bluetooth, wireless, etc.? With hearing aids, the wheel is reinvented frequently – most often as a result of smaller component availability or improvements in existing features.

To illustrate the three main factors involved in hearing aid development, the remainder of this post will highlight major developments (primarily hardware) that shaped the changes to hearing aid design. This post is intended primarily for those who are not familiar with the historical development of hearing aids, although it was a featured presentation by this Editor at the American Academy of Audiology in 2013.

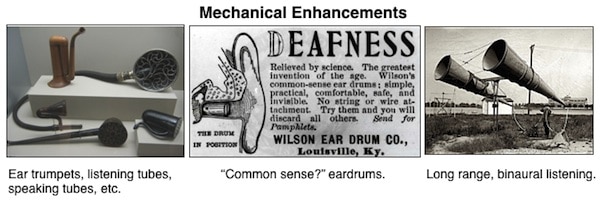

Mechanical Enhancements

Devices relying on mechanical enhancement of sound transmission reception gained prominence in the 17th century, but continued into the early 1900s. These consisted primarily of ear trumpets, listening tubes, speaking tubes, etc.

Electrical Amplification

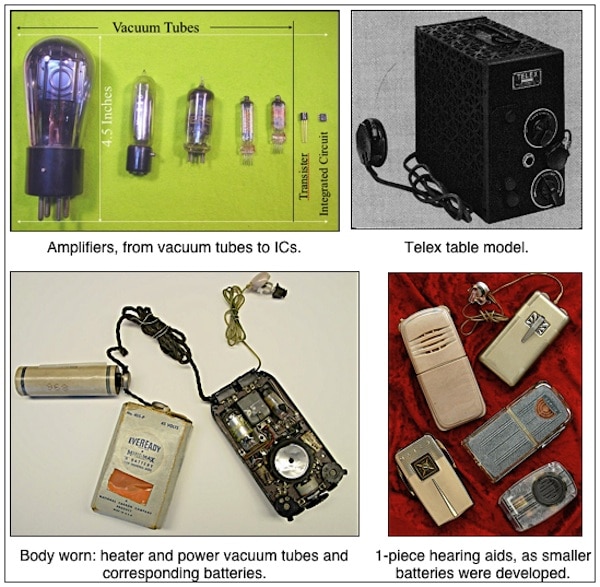

Current flow, and control, is the heart of the electrical hearing aid amplifier. The function is to efficiently deliver amplified power to a speaker (often called a receiver in hearing aid terminology). The historical development of hearing aid amplifiers involved three distinct developments:

- Carbon microphones/amplifiers (1900-1939)

- Vacuum tubes (1921-1953)

- Transistors (1953 – and continuing)

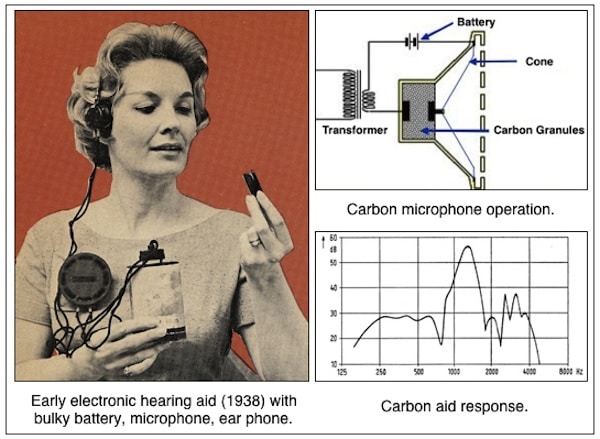

Carbon Microphones/amplifiers – 1900-1939

The carbon microphone (carbon transmitter) was developed in 1938. This was the first electrical hearing aid. The carbon microphone consisted of two metal plates separated by granules of carbon. Carbon movement was made to amplify electrical current. This essentially boosted weak signals (amplification). In functioning as both a microphone and an amplifier, the carbon microphone was ahead of its time. If greater power was required with the carbon microphone, the battery voltage could be increased, additional microphones could be added, or a resonating box could be employed.

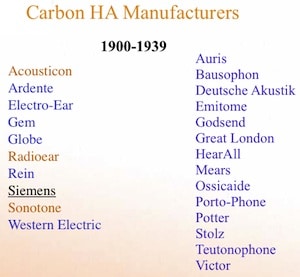

From an historical view, the following companies manufactured carbon hearing aids. The only company still in existence as an original manufacturer is Siemens. Older practitioners in the discipline of hearing might remember the names of those companies with gold color emphasis.

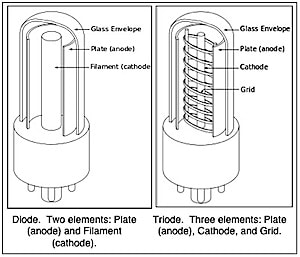

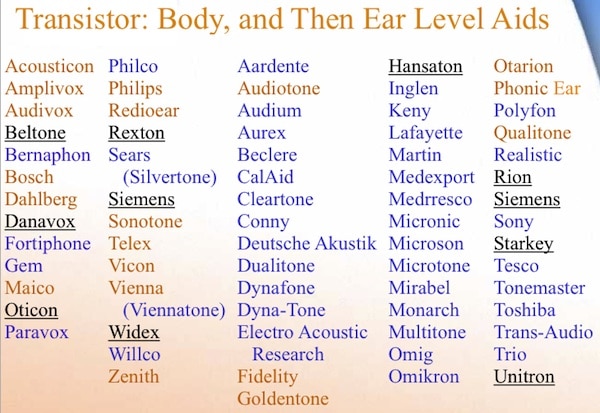

Vacuum Tube Hearing Aids – 1921-1953

The principle of the vacuum tube is that heat escapes from a filament (cathode) and is captured by a plate (anode). The hearing aid required two supply voltages:

- One to heat the cathode (the heater), called the A battery

- One to provide power to the plate, called the B battery

The vacuum tube itself had an earlier introduction, with the diode (1904) invented by John Ambrose Fleming, and the triode (1906) by Lee DeForest. The latter development was the real key to amplification in general, and for hearing aids specifically. DeForest placed a grid between the filament and plate. This allowed for control of electron flow by varying the grid voltage. This controlling feature is called amplification.

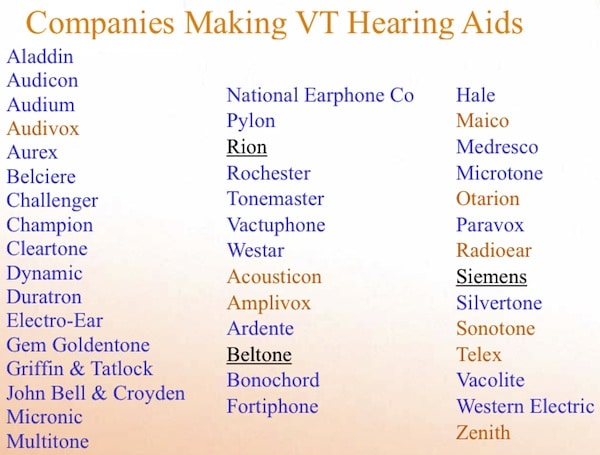

Continued smaller size and lower current consumption led to the development of smaller batteries, and hence, smaller hearing aids. Early units were table models carried in cases – like early camera boxes.

Body-worn hearing aids appeared in the mid 1930s, consisting of a multi-piece design (because of large battery sizes). One part consisted of the amplification electronics, the other two parts included one battery that supplied the heater vacuum tube, and the other supplied the power vacuum tubes.

One-piece hearing aids were developed in 1945 as a direct result of battery design improvements, allowing batteries to be made in smaller size. They still required two batteries, one for the heater, and the other for power. Vacuum tube improvements allowed for finer control of volume, and potentiometers were added leading to the use of a volume control wheel, control of tone (frequency response), and to AGC (automatic gain control).

Companies that made vacuum tube hearing aids are listed in the following table, with those still manufacturing in black and underlined, and others no longer manufacturing under their original umbrella, but names one might be familiar with, in gold.

Enter the Transistor (1953)

The transistor performs in many ways like the vacuum tube amplifier, but with the following differences:

- It controls current, whereas the vacuum tube controlled voltage.

- It is smaller, and stable under vibration and mechanical hazards.

- There is no filament to heat, and so, no need for an “A” battery.

- It has lower inherent noise and increased amplification. However, the transistor required greater operating voltage, and hence, the development of the silver-oxide hearing aid cell.

The transistor amplifies sound, and as such, eliminated vacuum tubes. The first use of an all-transistor hearing aid occurred in 1953. It was a body-worn aid. Eyeglass, behind-the-ear (over-the-ear, post-auricle), in-the-ear, in-the-canal, and other hearing aid configurations followed. The Table below lists the names of companies that made transistor body hearing aids, and then continued with ear level units. Again, those in Black continue to exist today, those in gold are most likely recognized by those who have been in the field for several years, and those in blue are no longer in business, and that readers are less prone to identify.

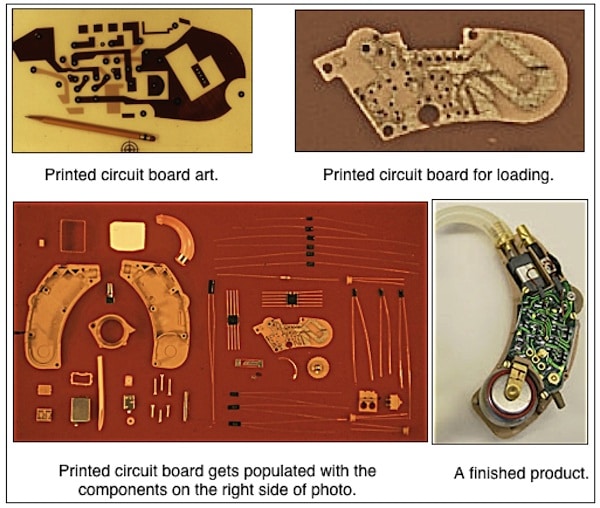

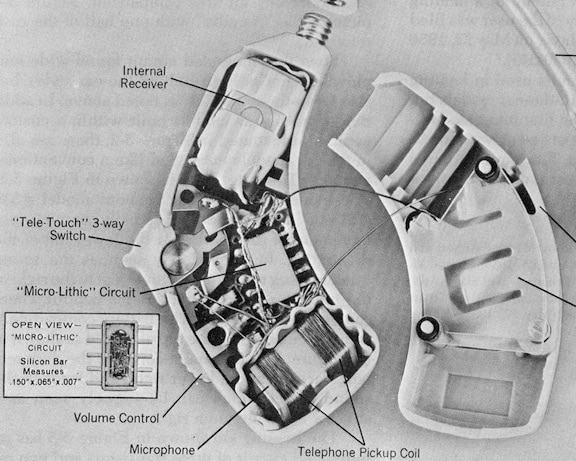

Printed Circuits

These first appeared in hearing aids in 1948, but were not commonly used in hearing aids until the 1970s. These printed circuit boards reduced the assembly time, which previously involved assembling many small individual components that required around 65 soldering connections. Soldering was not eliminated with printed circuit boards, but it was reduced substantially, as many “cold solder” connections were no longer needed.

Integrated Circuits (1958-1959)

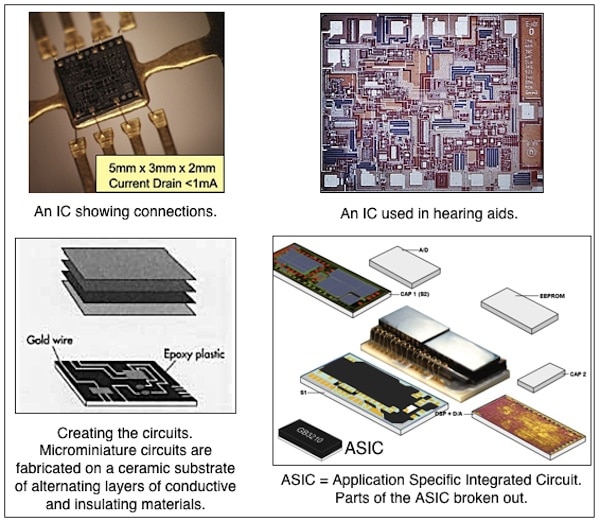

Integrated circuits consist of an entire circuit created in a single step. All individual components (capacitors, resistors, transistors, wires) soldered into a printed circuit, were now made from silicon. The first integrated circuits were considered “solid state” in that they were made from a single crystal. Integrated circuits (ICs) allowed for substantial miniaturization of hearing aids.

The IC concept was developed by Jack Kilby of Texas Instruments in 1958. He found a way to place individual components on a crystal. In 1959, Robert Noyce (Fairchild Semiconductor) enhanced the concept by integrating all into a unitary, or Integrated Circuit (IC).

The concept is based on building masked “layers” from bottom up in silicon. This allows for millions of transistors to be placed on a small chip. When being fabricated, hundreds are made on a single wafer at the same time, and then sliced apart later. ICs made for dedicated performance are known as ASICs (Application Specific Integrated Circuits).

(Next week’s post wills finish this “ride through history” of hearing aid technology and techniques).