Design Considerations Involved in Going From Analog to Digital Technology

Last week’s post provided background on how the first wearable digital hearing aid was developed. This post will continue this historical highlight leading to one of the most disruptive developments related to hearing aid technology – the digital hearing aid. Specifically, this post will discuss the design features/considerations of the Audiotone prototype instrument.

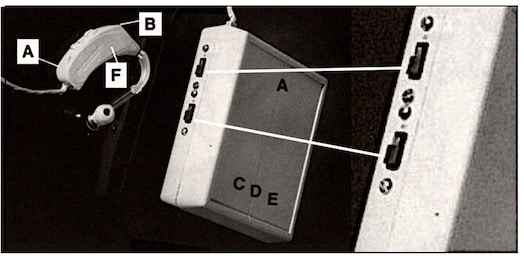

Figure 1. Switches on the digital hearing aid prototype that allowed the listener to perform a paired-comparison of the analog hearing aid. The top switch was an ON/OFF, and the bottom switch allowed for selection between an analog and digital hearing aid function.

Figure 1 shows the switching that allowed the listener to power the system (ON/OFF top switch), and a bottom D/A switch to select between digital (D) or the analog (A) amplification. It was determined that this was the best way to allow for a realistic paired-comparison of an analog to a digital hearing aid. Recall, that up to this time, it was not known how a wearable digital hearing aid would compare with an analog aid because its end signal was based on sampled data rather than all the data as in an analog system.

Adaptive Features

At low background noise levels, a slightly higher gain in the digital aid was designed. Because the digital aid had adaptive gain, this comparative apparent gain changed with ambient noise level, and the two aids appeared to have identical gains in noisier environments. Inside the digital processor were three “pots.” One adjusted the offset in the average level circuit, thereby determining how noisy the environment had to be before any adaptation occurred. A second pot adjusted the attack time in the average level circuit, and a third pot adjusted the release time. Two miniature plugs were added to the DSP processor to allow for two hearing aids (binaural listening).

From Analog to Digital

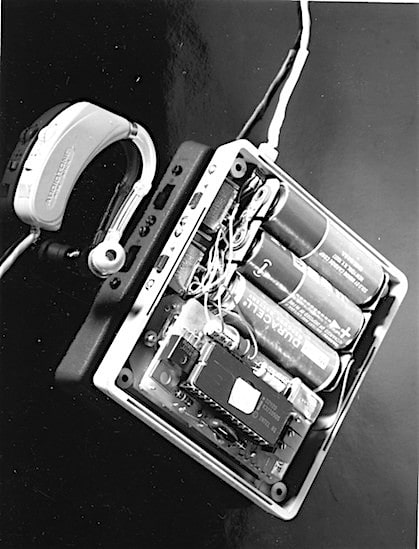

Figure 2. The “insides” of the Audiotone digital hearing aid processing system.

An inside view of the Audiotone digital aid is shown in Figure 2. A first most noticeable component is the power supply – three, 1.5 Volt batteries. The circuit design had to be made to “fool” the processor into thinking that it was actually operating on 12 volts (the lower power limit of DSP chips at the time), when it wasn’t. Much of the power was required for the high current drain of the DSP processor, an issue that was resolved in 1996 by Widex to allow the DSP to function on 1.4 Volts.

The DSP primary chip was an Intel 2920 Signal Processor. It was out-boarded with a voltage regulator, a quad op-amp, at least 21 resistors, 12 capacitors, 2 potentiometers, 3 diodes, a circuit board, and a 5MHz crystal clock. These were used for op-amp biasing, anti-aliasing, biasing, gain management, filtering, time constants, smoothing, rectification, sample and hold, and other functions. One hundred ninety-seven lines of instruction were written in the software code to manage the amplified performance. The BTE unit contained a separate 1.5 Volt hearing aid cell for its operation as an analog hearing aid (to compare with the digital hearing aid).

Comments from engineering at the time (May 25, 1983) stated that the circuit board could be further reduced in size and smaller batteries could be used. Continuous use with the batteries supplied was conservatively estimated at least 15 hours on the negative supply and three times that on the positive supply.

Noise Management

Recognizing that listening in the presence of background noise was the main complaint of hearing aid wearers, Audiotone made the decision to use the power of digital signal processing (DSP) to adaptively improve the signal-to-noise (S/N) ratio rather than waste its potential in modifying electroacoustical changes in the hearing aid. A number of proprietary algorithms (complex mathematical formulae) were developed and tested to accomplish this function. A first step was the decision to use a least mean square (LMS) algorithm as a foundation, and advance from there.

Two Microphone Inputs Added

A LMS noise reduction system requires two input signals – a primary input microphone that receives both the signal and the noise, and a second reference microphone to remove the noise from the signal. In reality, the noise to both microphone inputs could be essentially the same. The difference was that the reference microphone signal was routed through a filter. The resultant output was subtracted from the primary input (called the error), with the error looped back to the adaptive filter whose filter weights automatically adjusted in response to the error signal. The LMS filter adjusts (adapts) itself until the error term is minimum. Through this activity, the resultant output from the filter is the desired signal. Any noise correlated at the two inputs is cancelled, resulting in an improved S/N ratio, with background noise removed, and the primary signal (hopefully speech) being retained.

This system works very well when the two microphones can be physically separated by distance, and with the primary mic close to the speaker and the reference mic some distance away immersed in the noise. It was realized that when wearing hearing aids, this distance separation between the mics was not possible, limiting the usefulness of a two mic system.

Understanding this, Audiotone devised a unique system in an attempt to separate a primary from a secondary signal. Two microphones were placed in each hearing aid. The primary microphone was an omnidirectional microphone, and the reference microphone was a directional microphone (at that time single unit devices, not the two-mic types used today) with its normally forward-facing port facing backwards to pick up the greatest amount of sound from the rear! A few of the more recent digital noise cancellation hearing aids have now employed something similar.

Digital Had to Be as Good as Analog

One of the requirements of the design was that the digital aid be at least as good as an analog aid, or there was no sense in further development. This proved to be the case. The prototype proved a success in showing that a digital hearing aid could be built. But, it also provided three additional remarkable breakthroughs: The ability of the digital aid to (1) adapt to changing signals using a microprocessor having an adaptive filter algorithm (2) provide noise suppression, and (3) to perform these functions in real time.

Final Status

The DSP circuit was later refined as a Model DHA-X2A with continued development supplied by the DSP Group of Israel (Figure 3), but the project was terminated in 1987, shortly after Audiotone was acquired by Dalhberg, and the focus was shifted to the design of programmable hearing aids.

Figure 3. Audiotone Model DHA-X2A wearable digital hearing aid without attached BTE hearing aid components.

Your article prompted me to dig out my A-2000 programmable hearing aids and the “System 2000″programmer. I think this stuff is from 1988. I remember going to Audiotone one day and you or Jim took me back to look at the breadboard for the “future of hearing aids”. I have a vivid image of that board and couldn’t believe that I was allowed to see it (on the condition of greatest confidentiality),

Bob:

I still have about 3 or 4 of these units here as well. In fact, I tried to program one a few weeks ago but did not have the proper card to be inserted. Other than that, I believe they all work. Unlike some companies, even at that time, Audiotone was rather open to visitors in the engineering area as we worked on new products. I found out later, as I visited other manufacturers, that such openness was not allowed. Heck, we were proud of what we were doing and if a customer made a comment about the product, we had a tendency to listen to them.