Current, to Alternative, Directional Microphone Technologies

Aart van Halteren, M.Sc., Chief Technical Officer, Sonion, The Netherlands.

Ann-Marie Sänger, Senior Product DevelopmentEngineer, Sonion, The Netherlands

This post is based on a Technology Update presentation given at the American Auditory Society Meeting in Scottsdale, AZ, March, 2015. It has been modified by the editor, taking it from a PowerPoint presentation to this readable version.

The development of better directional microphone alternatives that are more robust in their day-to-day use now exist. The overall end goal of directional microphone development is to improve the signal-to-noise ratio (SNR), in line with the main goal for hearing aids, which is to improve speech intelligibility, especially in noisy situations. This, and a following post, will compare the different systems with respect to how directional microphones function, and explain the tradeoffs with respect to robustness versus other parameters.

Introduction

Microphone technology for hearing aids has undergone many changes since the first carbon microphones were introduced around 1900. This presentation will continue to highlight these changes, concentrating on robust adaptive directional microphone performance. In doing so, this, and a following post, will look to three areas of interest:

- Speech in noise

- Industry standard matched pair for directional performance, and

- Microphone modules designed to introduce redundancy to increase robustness.

Speech in Noise

Healthy human hearing has natural directivity. Unfortuntely, most of this directivity is lost when using a hearing aid. This is unfortunate because directionality (being able to localize the source sounds) has been proven to be THE most successful way of enhancing intelligibility of speech in noise for the hearing aid user.

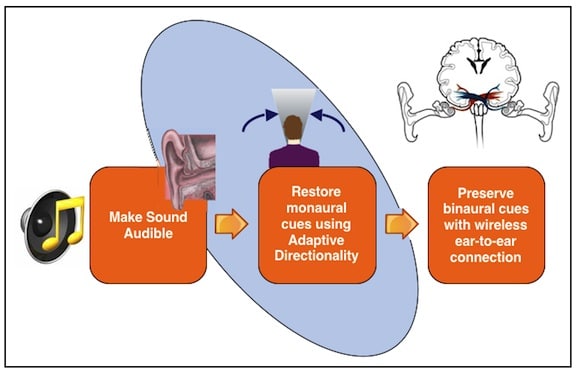

The evolution of speech intelligibility (especially in noise) in hearing aids can be illustrated as in Figure 1. The first goal was to make sound audible, followed by the restoration of monaural cues using adaptive directionality, and most recently, by preserving binaural cues with wireless ear-to-ear connection. The industry is well past the first goal, that of making sounds audible, and is currently focusing more on the continuation of monaural cue restoration and expansion into improving binaural cues.

Figure 1. Evolution of speech intelligibility in hearing aids. The industry has developed beyond the first goal, that of making sound audible, and continues to improve upon and expand goals two and three.

Current Industry Standard for Microphone Technology

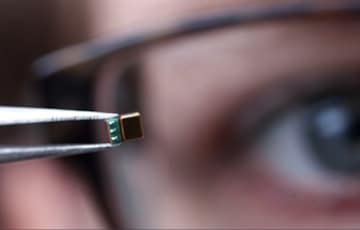

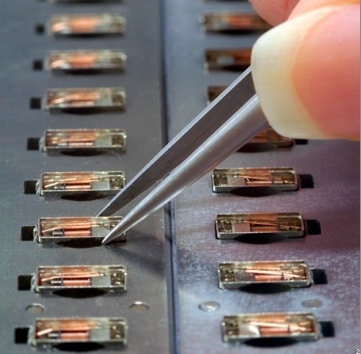

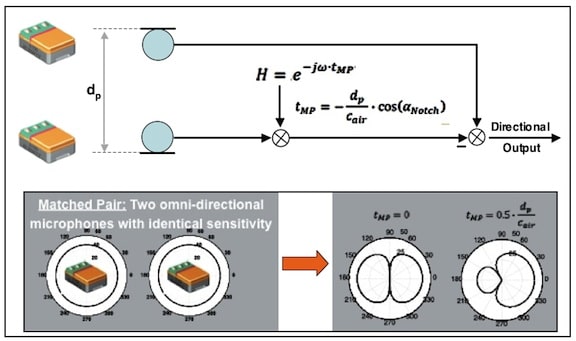

The current industry standard is to provide for directional hearing using adaptive directionality. This involves the use of two omni-directional microphones with identical sensitivity (Figure 2), creating directional listening performance using signal processing algorithms. (Early directional microphones consisted of a single microphone having a front and rear opening, with sound received by the rear opening delayed, resulting in a directional polar pattern).

Figure 2. Hearing aid industry standard matched pair of omnidirectional microphones using signal processing algorithms to create directional microphone patterns covering the range of polar plots shown on the lower right.

What if the Microphones are Not Matched?

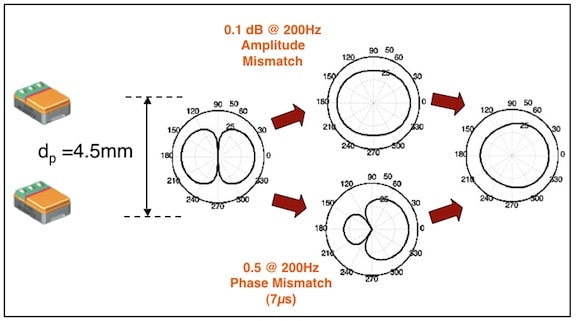

For proper directionality to occur, the two omnidirectional microphones must be perfectly matched when operating in the hearing aid. Hearing aid manufacturers employ signal processing algorithms to ensure that they are perfectly matched. But, what if they are not, in either amplitude or phase? The result is a mismatch as illustrated in Figure 3.

Figure 3. The results of a mismatched pair of omnidirectional microphones – mismatched either in amplitude or in phase. The end result is an ineffective directional microphone polar pattern. dp is the distance between the two microphone openings.

Influence of Sensitivity Mismatch on the Directivity Index

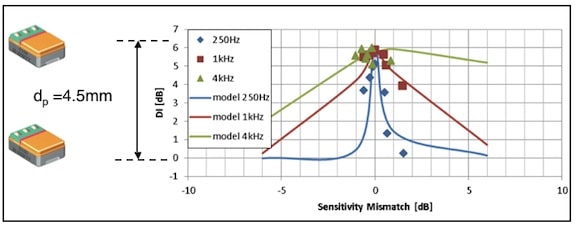

Figure 4 shows the plotted results of sensitivity mismatch at the frequencies of 250, 1000, and 4000 Hz on the DI (directivity index). The DI compares sounds originating in front to sounds originating from all other locations around the hearing aid (HA). The higher the DI the more directional the HA is. Notice that the DI changes dramatically with even minor sensitivity mismatches – more apparent with 250 and 1000 Hz than 4000 Hz.

Figure 4. Influence of microphone sensitivity mismatch on the DI (directivity index). The individual plots (diamonds, squares, and triangles) were from a batch of tuned omnidirectional microphones.

How Can Matching be Degraded?

Omnidirectional mismatch for directional performance can occur due to:

- Handling in production

- Ambient humidity changes

- Ambient temperature changes

- General aging of components

The obvious solution is to make the microphones more robust against mismatch. Another solution is to develop a directional technology that is more tolerant for mismatch. This will be the topic of next week’s post.